Brick Molding Machine: Transforming Construction with Advanced Technology

Moderno brick molding machines have significantly transformed the construction industry by incorporating advanced technology that enhances efficiency, precision, and sustainability. KBL Maquinaria has integrated cutting-edge automation into its brick molding machines, allowing manufacturers to produce high-quality bricks with minimal manual intervention. These machines optimize material use, reduce waste, and ensure consistent brick size and strength, all while speeding up production cycles. This makes it easier for businesses to meet growing demands without compromising on quality.

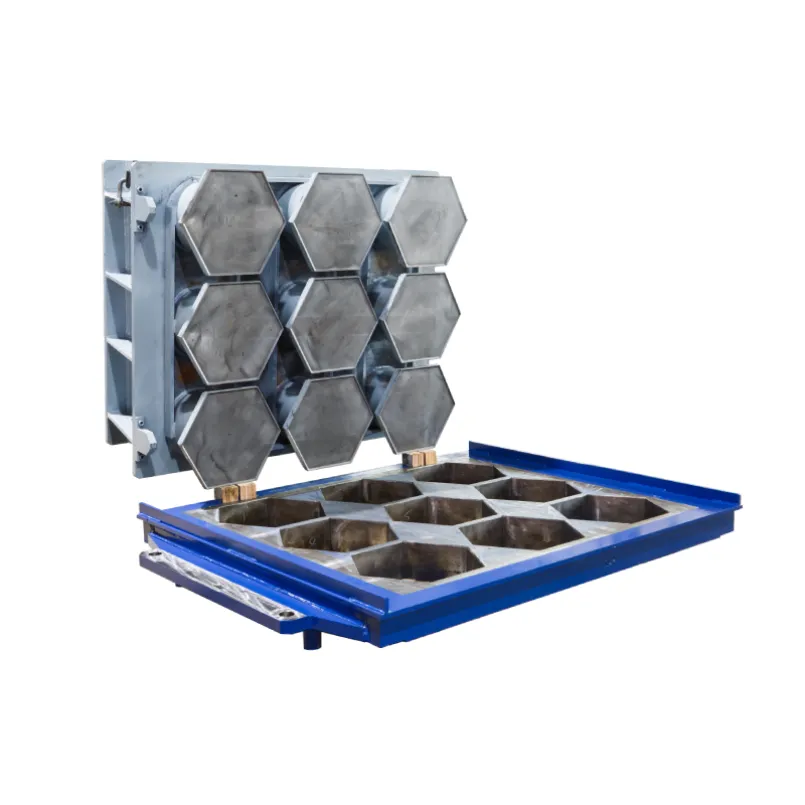

One of the key technological advancements in brick molding machines es el uso de sistemas hidráulicos. KBL Maquinaria utilizes hydraulic pressure to produce denser, stronger bricks, ensuring long-lasting durability for construction projects. This process not only enhances the structural integrity of the bricks but also promotes eco-friendly production by using less energy. The precision of the hydraulic systems allows for superior control over the entire production process, ensuring that every brick meets industry standards for strength and quality.

De cara al futuro, KBL Maquinaria is at the forefront of incorporating smart technology into their machines. Their máquinas para fabricar ladrillos are now equipped with real-time sensors and data analytics, enabling operators to monitor production remotely, diagnose issues, and optimize machine performance. This combination of automation, hydraulic efficiency, and smart technology ensures that KBL Machinery's machines remain leaders in the industry, providing innovative and reliable solutions for construction businesses.

Key Benefits of Using a Hydraulic Brick Molding Machine

- Superior Brick Strength: The hydraulic systems in KBL Machinery’s brick molding machines apply consistent pressure, creating denser and more durable bricks suitable for a wide range of construction needs.

- Eficiencia energética: Hydraulic-powered máquinas para fabricar ladrillos de KBL Maquinaria are designed to minimize energy use while maintaining high performance, making production both cost-effective and environmentally friendly.

- Precisión y coherencia: The advanced hydraulic technology guarantees uniformity in size and quality, reducing material waste and improving production efficiency.

- Mantenimiento reducido: KBL Machinery’s brick molding machines are built to last, requiring less maintenance than traditional mechanical systems. This reduces downtime and extends the life of the machines, providing long-term savings for manufacturers.

| Key Features of KBL Machinery's Hydraulic Brick Molding Machines | Beneficios |

|---|---|

| Superior Pressure Application | Creates denser, stronger bricks |

| Energy-Efficient Operation | Reduces energy consumption and costs |

| Real-time Production Monitoring | Optimizes performance remotely |

| Durabilidad y bajo mantenimiento | Ensures longer machine life and fewer repairs |

KBL Maquinaria: Un proveedor de equipos de construcción de confianza

Como líder proveedor de maquinaria de construcción, KBL Maquinaria is committed to delivering top-quality máquinas para fabricar ladrillos y Máquinas para fabricar bloques to businesses around the world. Our advanced technology ensures superior product quality, operational efficiency, and sustainability. We specialize in providing customized solutions that meet the specific needs of our clients, from small-scale projects to large industrial applications.

En KBL Maquinaria, we not only focus on delivering reliable machinery but also prioritize exceptional customer service. From initial consultations to after-sales support, we work closely with our clients to ensure that their production processes are optimized for success. Our commitment to innovation, combined with a customer-first approach, has earned KBL Maquinaria a reputation as a trusted partner for businesses worldwide.