Moulds for Interlocking Blocks: The Future of Brick Making Machines with Technology and Automation

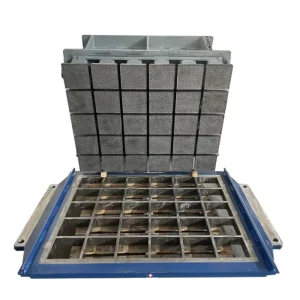

The future of brick making is evolving at an unprecedented pace, led by KBL Machinery with its state-of-the-art moulds for interlocking blocks that drive innovation. Modern brick making technology is smarter and faster, with KBL Machinery's automated systems significantly reducing manual labor while ensuring precise quality control. By integrating AI and machine learning, KBL Machinery allows for optimized production cycles, monitoring of raw material usage, and prediction of maintenance needs. These technological advancements not only improve efficiency but also enhance the overall quality and consistency of bricks produced through moulds for interlocking blocks.

Automation also plays a crucial role in reducing the environmental impact of brick manufacturing, an area where KBL Machinery excels. Through automation, energy consumption is lowered, resulting in a reduced carbon footprint. KBL Machinery’s machines can integrate recycled materials like fly ash and slag into the production process, contributing to eco-friendly manufacturing. As automation becomes more sophisticated, KBL Machinery's Blockformen will continue to evolve, providing greater control and customization, enabling manufacturers to meet specific project requirements with minimal waste and maximum efficiency.

Looking forward, moulds for interlocking blocks will be defined by even greater connectivity and data-driven insights. KBL Machinery is actively investing in smart technology, enabling operators to remotely monitor production in real-time, access performance analytics, and make informed decisions to optimize operations. As the construction industry shifts towards more automated and eco-friendly solutions, KBL Machinery is positioned as the leading Lieferant von Baumaschinen, providing advanced, reliable, and sustainable brick-making solutions.

Wie man mit der richtigen Maschine ein Blockherstellungsunternehmen gründet

- Bewertung der Marktnachfrage: Analyzing local demand for different block types is essential. This will help you choose the right machine and block moulds for the blocks you plan to produce.

- Wählen Sie die richtige Blockherstellungsmaschine: Choose a machine from KBL Machinery that aligns with your production needs. Consider automation level, production capacity, and versatility in block types to ensure efficient production.

- Standort und Raum berücksichtigen: Set up your block manufacturing plant in a location with ample space for road brick moulds, raw material storage, and block curing. Ensure easy access to your target market for efficient distribution.

- Finanzierung sichern: Determine the costs of a block moulds machine, raw materials, labor, and other expenses. Develop a financial plan and secure funding through loans, investors, or personal savings to start your business.

- Schulung Ihrer Arbeitskräfte: Once you've acquired a machine from KBL Machinery, invest in employee training. Proper training ensures smooth operations, minimizing production downtime.

Über KBL Machinery

KBL Machinery is a leading manufacturer of high-performance moulds for interlocking blocks and other innovative block-making equipment, providing cutting-edge solutions for the construction industry. With a focus on quality, efficiency, and sustainability, KBL Machinery offers machines that cater to a range of production needs, from small projects to large-scale industrial applications. Our commitment to technology and sustainability ensures that each machine is designed for optimal performance, energy efficiency, and durability, establishing KBL Machinery as a trusted Lieferant von Baumaschinen worldwide.

| Key Aspect | Beschreibung |

|---|---|

| Automation | Reduces manual labor and enhances quality control. |

| Energie-Effizienz | Lowers electricity consumption for eco-friendly production. |

| Material Integration | Supports recycled materials like fly ash and slag. |

| Remote Monitoring | Allows for real-time insights and data-driven adjustments. |

| Dauerhaftigkeit | Built for long-term, heavy-duty use. |

| Personalisierung | Supports specific project requirements with minimal waste. |

Wählen Sie KBL Maschinenpark for your moulds for interlocking blocks, Blockformenund road brick moulds needs ensures you’re investing in sustainability and advanced technology, giving you a reliable partner in building a greener future.