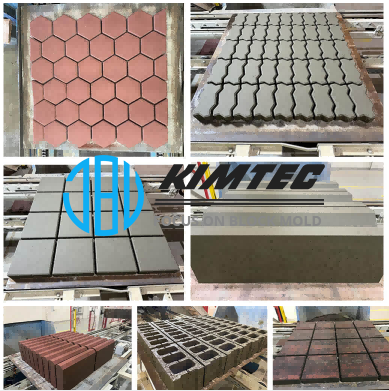

Hexagonal Concrete Molds, Interlocking Brick Molds

Brief Introduction:

1. Block Type:

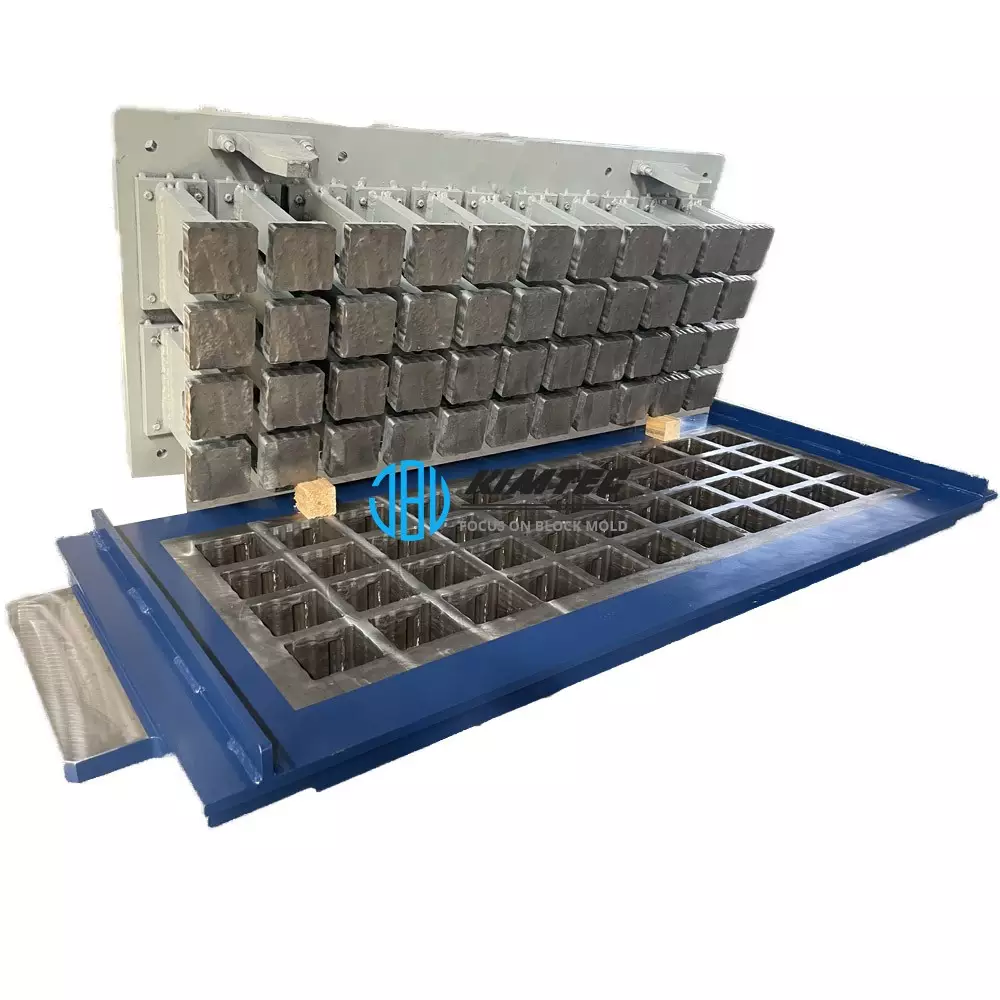

We design and manufacture high-quality steel molds for interlocking paving stones, slabs, permeable pavers, curbstones, retaining walls, hollow blocks, and specials, always meeting customer needs while suggesting innovative ideas.

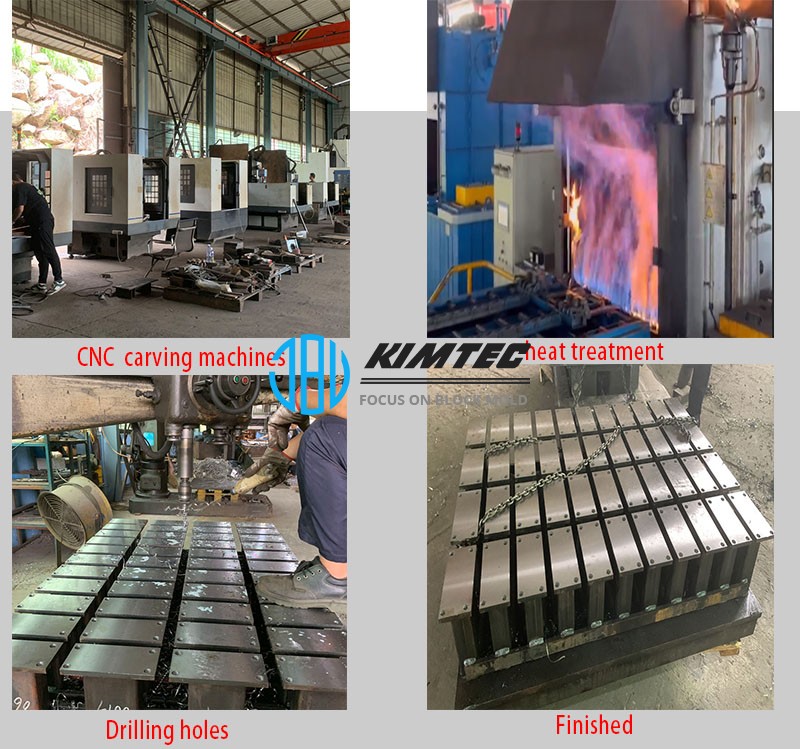

2. Raw Material:

For our concrete block molds, we use top-tier, quenched, and tempered steel from Italy, enhancing its durability through heat treatment for better abrasion resistance.

3. Manufacturing Experience:

With nearly 30 years of experience, we've served customers across many countries. By combining our expertise with premium steel, we ensure high-quality products for buyers like Masa, Hess, Zenith, Tiger, Bessel, Ritu, and more.

Mold Technical Details

Mold Features:

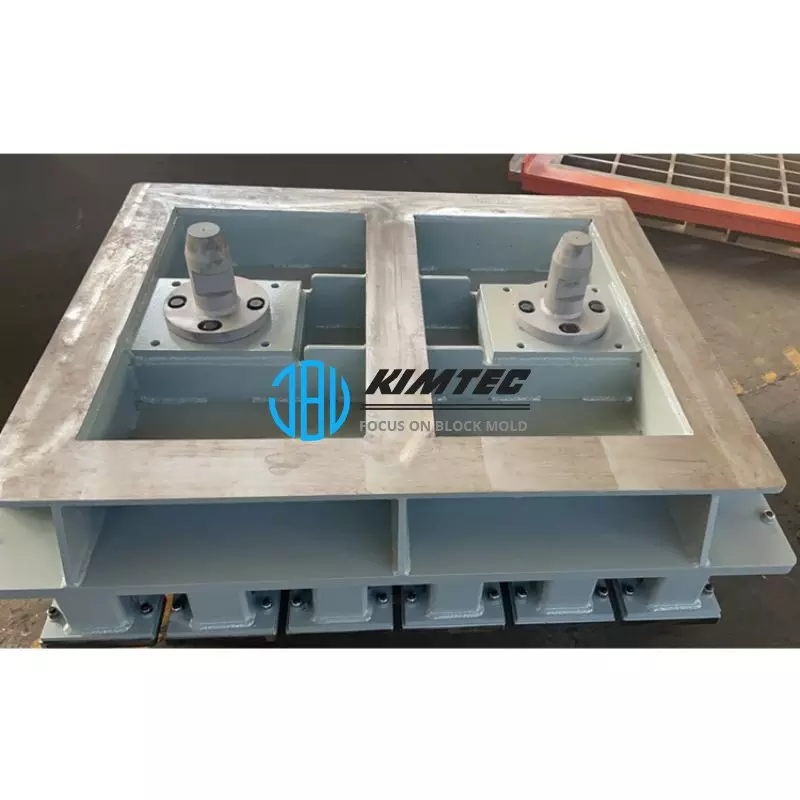

1. The Most Advanced Assembly Process:

A. We use advanced welding technology and de-stress treatment. If stress exists in the mold material, it can cause deformation during use, leading to errors in dimensions, shape, and position tolerances. This can result in product defects and make the components incompatible. To prevent this, we minimize deformation during heat treatment and perform tempering after quenching to eliminate internal stress.

B. The press foot clearance related to the machine ranges from 0.3 to 0.8 mm.

C. We use standard parts and apply anti-loosening treatment to high-strength connection bolts.

D. Our assembly process is standardized, allowing for easy part replacement.

E. We use high-quality, wear-resistant steel plates.

F. The mold has a damping function to reduce vibration.

G. We offer realizable digital free surface design.

2. Durability Treatment for the Mold:

To ensure durability, we apply carbonitriding heat treatment (60-65 HRC).

A. The die frame and press foot are hardened to 60-65 HRC.

B. The minimum hardening depth is 1.2 mm.

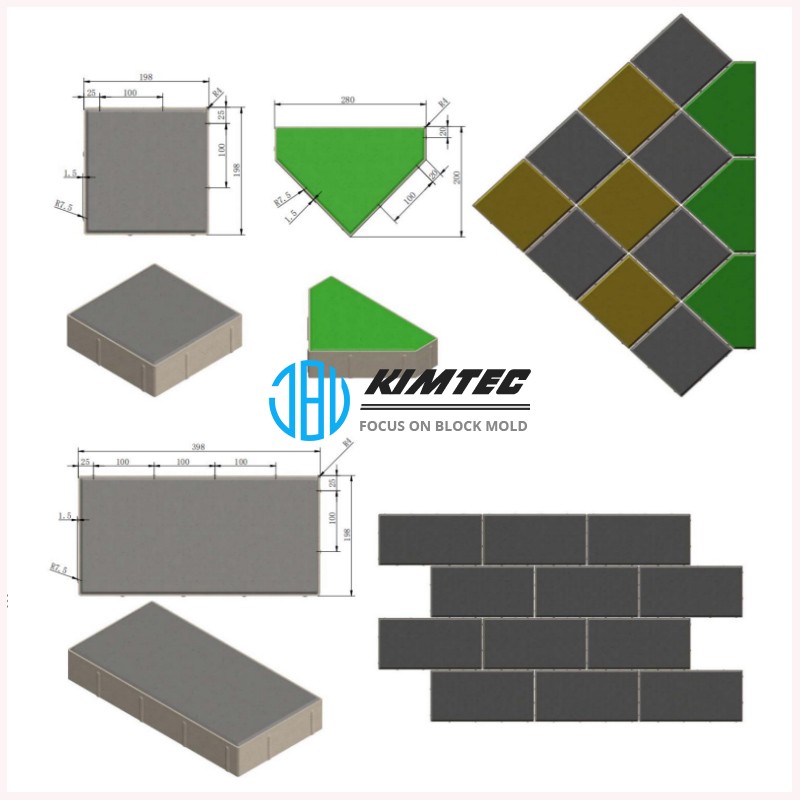

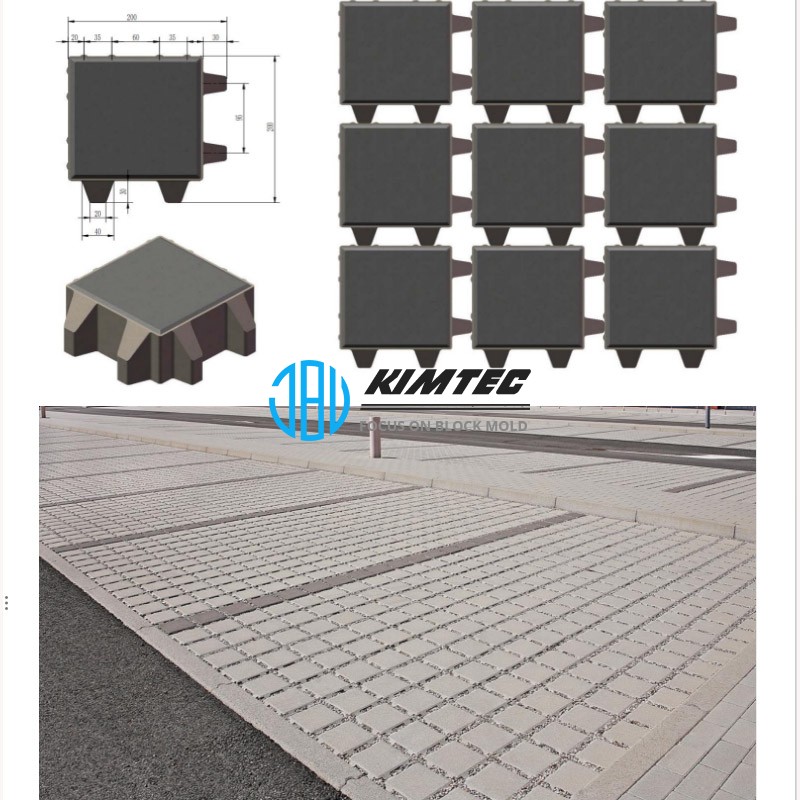

More Block Types for Your Reference

About Our Packing

FAQ:

1. How can I get a quotation?

A. If you have detailed drawings of the block you need, send them to us. We will provide a quote based on that.

B. If you don't have detailed drawings, tell us the block type you need, such as hollow or solid. You can also send a picture of the block and provide the dimensions (length x width x thickness in mm).

C. What is the size of your pallet?

D. What are the size and height of your tamper head and down mold?

E. How will your mold connect to your machine? If you have a connection drawing, please provide it. Once we have your information, we will send a quote ASAP.

2. What is the delivery time?

For standard block molds, delivery takes 20-25 workdays after we receive the deposit. For high-end block molds, delivery takes 30-40 workdays.

3. What about transport packaging?

We use wooden packaging with plastic film or pack according to the buyer's requirements.

4. How can I contact you?

You can contact us via WeChat/WhatsApp at +86-1330506196 or +86-18960287187. Thank you!