Energy-Efficient Machines for Molding Hollow Blocks: A Path to Sustainable Construction

Energy-efficient machines for molding hollow blocks are rapidly becoming essential in promoting sustainable construction practices. KBL Machinery leads the way in this space, providing advanced equipment specifically designed to reduce energy consumption while maximizing production output. These machines help manufacturers lower operational costs and reduce their environmental impact by utilizing innovative technologies, including optimized curing processes, automated controls, and minimal water usage. By adopting machines for molding hollow blocks, companies align themselves with global sustainability goals and regulations, making a positive environmental impact while gaining a competitive edge through reduced long-term costs and enhanced efficiency.

In addition to energy efficiency, machines designed for molding hollow blocks often incorporate sustainable materials, such as locally sourced or recycled raw materials. KBL Machinery’s machines enable the production of eco-friendly blocks that are free from harmful chemicals, meeting the growing demand for green building materials. With the construction sector increasingly focusing on eco-conscious projects, companies using these machines for molding hollow blocks can meet market demands and enhance their reputation. The adoption of sustainable practices in block production strengthens a company’s position as a leader in the expanding green building industry.

Beyond environmental benefits, machines for molding hollow blocks provide significant business advantages. Reduced energy usage leads to lower utility bills, and high production efficiency allows companies to meet deadlines more consistently. Additionally, the commitment to sustainability enhances a brand’s image, making it more attractive to eco-conscious clients and partners. In an era where corporate responsibility and profitability go hand-in-hand, investing in energy-efficient machines for molding hollow blocks supports long-term growth and industry leadership.

Five Key Factors to Consider When Choosing Block Moulding Equipment

- Production Capacity: When choosing equipment for molding hollow blocks, consider the production capacity carefully. Different machines are designed for varying output levels, from small-scale production to large industrial needs. Assessing both current and future production requirements will ensure you select a machine that meets demand and can scale as the business grows.

- Automation Level: Machines for molding hollow blocks are available in various automation levels, from manual to semi-automatic and fully automatic. Fully automated machines offer higher efficiency and lower labor costs but require a larger initial investment. Selecting the right level of automation depends on your labor resources, production speed requirements, and budget.

- Energie-Effizienz: Energy consumption is a critical factor for businesses looking to lower operational costs. KBL Machinery’s energy-efficient machines for molding hollow blocks are designed to minimize power usage while maximizing output, making them ideal for sustainable construction practices and reducing long-term energy costs.

- Quality of Output: Consistency in the quality of blocks produced is essential. Machines for molding hollow blocks should ensure that every block meets industry standards for strength, size, and durability. Reviewing sample blocks and evaluating the machine’s ability to handle different raw materials is crucial to preventing defects and waste.

- After-Sales Support and Maintenance: Choosing a reliable Lieferant von Baumaschinen that offers strong after-sales support is essential for uninterrupted production. KBL Machinery, known for its comprehensive technical support and training, provides prompt service and spare parts, ensuring that machines for molding hollow blocks continue to operate efficiently, reducing potential downtime.

Über KBL Machinery

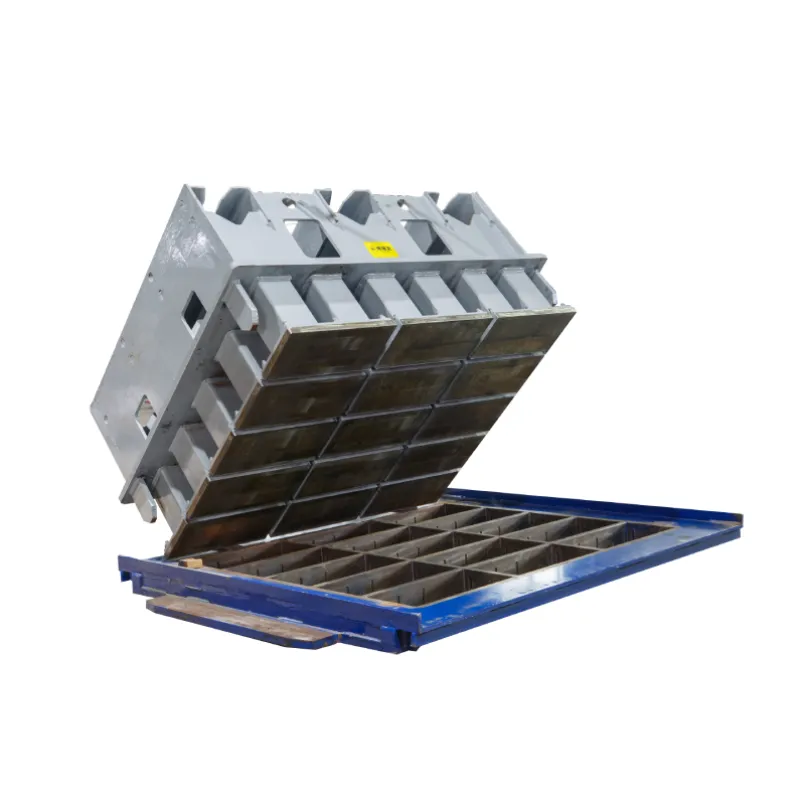

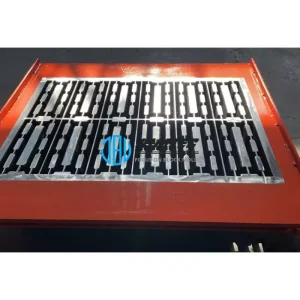

KBL Machinery ist ein führender Lieferant von Baumaschinen specializing in energy-efficient solutions for molding hollow blocks, Block-Formenund Formen für Straßenbausteine. Known for its commitment to innovation, quality, and customer satisfaction, KBL Machinery offers durable, high-performance equipment designed to meet diverse construction needs. By providing cutting-edge technology and excellent after-sales support, KBL Machinery ensures clients worldwide can achieve their production goals sustainably and efficiently. With years of experience and a reputation for reliability, KBL Machinery is the trusted choice for businesses looking to optimize their construction processes.

| Wichtigste Überlegung | Beschreibung |

|---|---|

| Production Capacity | Designed for various output needs, from small-scale to large industrial applications. |

| Automation Level | Offers manual, semi-automatic, and fully automatic options to meet different labor and production speed requirements. |

| Energie-Effizienz | Reduces power consumption, lowering energy costs and supporting sustainable practices. |

| Quality of Output | Ensures blocks meet standards in strength, size, and durability, minimizing defects and waste. |

| After-Sales Support | Comprehensive support, training, and spare parts availability from a reputable Lieferant von Baumaschinen. |