How Paving Brick Moulds are Transforming the Building Materials Industry

Innovative paving brick moulds are reshaping the building materials industry by bringing advanced automation and precision to brick production. KBL Machinery has designed state-of-the-art paving brick moulds equipped with automated controls, sensors, and real-time data analysis to enhance every step of the process, from material mixing to brick curing. This technology significantly reduces manual labor and ensures uniform brick quality in terms of shape, strength, and finish. Such precision allows manufacturers to minimize waste, use resources optimally, and reduce costs, enabling them to achieve high industry standards and maximize productivity.

Additionally, paving brick moulds from KBL Machinery contribute to sustainability efforts within the industry. These moulds are compatible with eco-friendly materials and utilize real-time data to optimize energy consumption, helping manufacturers lower their environmental impact. This shift toward sustainable production aligns with global green building initiatives, allowing businesses to meet the growing demand for environmentally responsible materials. By adopting KBL Machinery's paving brick moulds, companies not only enhance operational efficiency but also position themselves as leaders in sustainable construction.

Versatile and Cost-Efficient Block Moulds for Diverse Production Needs

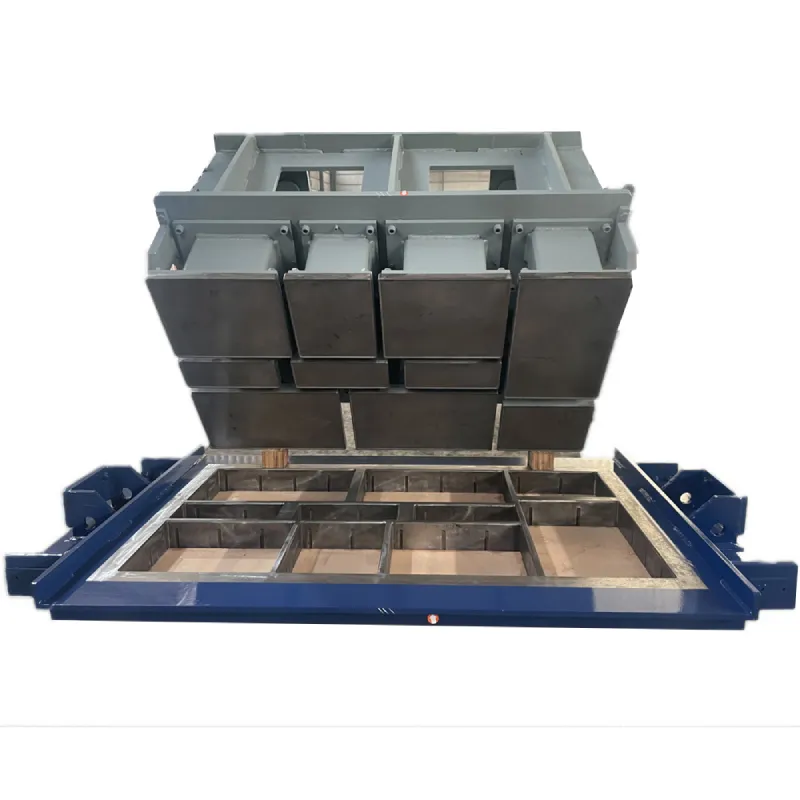

KBL Machinery's Block-Formen are designed to meet the evolving demands of the construction industry. From Road Brick Moulds to custom solutions, these moulds offer unmatched versatility and durability:

- Variety in Brick Types: Block Moulds can produce a range of bricks, including paving bricks, solid blocks, and decorative options, addressing multiple construction requirements.

- Adaptability to Materials: These moulds can work with various materials, including clay, sand, and cement, allowing flexibility in the raw materials used.

- Customization for Specific Projects: KBL Machinery’s moulds can be customized to meet project-specific requirements, ensuring flexibility and quick adaptation to changing demands.

- Gesteigerte Produktionseffizienz: Designed to streamline processes, KBL Machinery’s moulds reduce production downtime and increase output.

- Cost-Effective: By using multi-functional Block Moulds, manufacturers save on equipment and maintenance costs, maximizing investment returns.

| Merkmal | Vorteile |

|---|---|

| Advanced Automation | Ensures high precision and reduces manual intervention, improving consistency and reducing waste. |

| Customizable Moulds | Quick adaptation to custom specifications, ideal for a variety of projects. |

| Energie-Effizienz | Lowers energy use, supporting sustainable practices and reducing operational costs. |

| Langlebige Konstruktion | Made with quality materials for long-term use and low maintenance needs. |

| Comprehensive After-Sales Support | KBL Maschinenpark provides technical support, training, and spare parts, ensuring reliable operation. |

KBL Machinery - Trusted Construction Equipment Supplier

Als ein führendes Lieferant von Baumaschinen, KBL Machinery is committed to delivering high-quality paving brick moulds, Block Moulds, and Formen für Straßenbausteine that drive efficiency and innovation in brick production. With a focus on sustainability, advanced technology, and unmatched customer support, KBL Machinery provides comprehensive solutions for businesses of all sizes. Choosing KBL Machinery means partnering with an industry leader dedicated to quality, innovation, and supporting client success in the competitive construction market.