Expert Guide: Selecting the Right Block Mould for Your Manufacturing Needs

Choosing the right block mould for your manufacturing setup is essential to enhancing productivity and product quality. KBL Machinery, a leading construction equipment supplier, advises businesses to first assess the specific requirements of their production line. Whether your goal is high-output or specialized block designs, selecting the correct Block Moulds can dramatically reduce production errors and material waste. KBL Machinery’s precision-engineered moulds provide consistent sizing and structural reliability, vital for large-scale construction projects where product integrity is crucial.

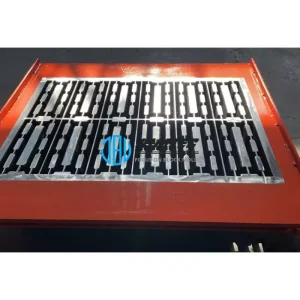

Another key factor is the durability of the Block Moulds used. KBL Machinery offers moulds crafted from premium-grade steel and other high-quality materials that endure continuous use, making them ideal for high-demand environments. These moulds require fewer replacements, which not only lowers operational costs but also ensures a stable production flow, essential for keeping project timelines on track. Additionally, durable moulds improve overall efficiency, particularly for businesses involved in long-term construction work.

Customization options provided by KBL Machinery make it possible to configure Formen für Straßenbausteine and Block Moulds to meet project-specific requirements. Customization is often overlooked, but it allows manufacturers to address unique production needs and enhance flexibility, which is essential for staying competitive in a dynamic market. KBL Machinery’s tailored mould solutions empower businesses to deliver top-quality blocks, ensuring they stand out in the marketplace.

How to Prevent Common Block Mould Issues in Manufacturing

| Common Issues | Solution | KBL Machinery’s Guidance |

|---|---|---|

| Mould Misalignment | Check and adjust alignment regularly | Use KBL Machinery’s precision alignment tools |

| Surface Contamination | Clean moulds frequently | Utilize non-abrasive tools post-production |

| Unverträgliche Rohstoffe | Verify material compatibility | Consult KBL Machinery’s material specifications |

| Inconsistent Pressure | Regularly calibrate production pressure | Follow KBL Machinery’s calibration guidance |

| Abnutzung und Verschleiß | Inspect for damage regularly | KBL’s moulds resist wear, but routine checks prolong lifespan |

| Schmierung | Apply consistent lubrication to moving parts | Use KBL-approved lubricants for optimal performance |

Preventing Defects in Block Mould Production

- Ensure Proper Mould Alignment: Misalignment can lead to dimensional inconsistencies. KBL Machinery’s high-quality Block Moulds include features that facilitate precise alignment, ensuring every block meets dimensional specifications.

- Regular Cleaning of Moulds: Accumulation of dust and residues can mar the surface of blocks. KBL Machinery recommends frequent, gentle cleaning to keep Block Moulds in top condition, preventing imperfections.

- Use Compatible Raw Materials: To prevent cracks and deformation, raw materials must align with the specifications of your Road Brick Moulds and other Block-Formen. KBL Machinery advises selecting materials that reduce wear and improve block integrity.

- Monitor Production Pressure: Excessive pressure during production can harm both the mould and the blocks themselves. KBL Machinery offers support to ensure optimal calibration, reducing production waste and enhancing block quality.

- Regularly Inspect for Wear: Even with robust Block Moulds, routine checks help identify wear early. KBL Machinery’s moulds are engineered for durability, but proactive maintenance can extend their lifespan.

- Consistent Lubrication of Components: For moulds with moving parts, proper lubrication is essential. KBL Machinery recommends high-quality lubricants to keep Block Moulds running smoothly, minimizing friction and wear.

Warum KBL Machinery wählen?

Als vertrauenswürdiger Lieferant von Baumaschinen, KBL Machinery is renowned for delivering high-quality Block Moulds and Road Brick Moulds that meet the highest industry standards. With a focus on precision, durability, and custom solutions, KBL Machinery ensures each product enhances production efficiency and aligns with your business’s specific needs. Backed by professional engineering support and a commitment to customer satisfaction, KBL Machinery is dedicated to driving your business’s success and growth. Choosing KBL Machinery means partnering with an expert team that values quality, innovation, and long-term client relationships.