China's Leading Kerb Stone Mold Manufacturer for MASA HESS Machines

Technical Details of Our Molds

Features of Our Molds

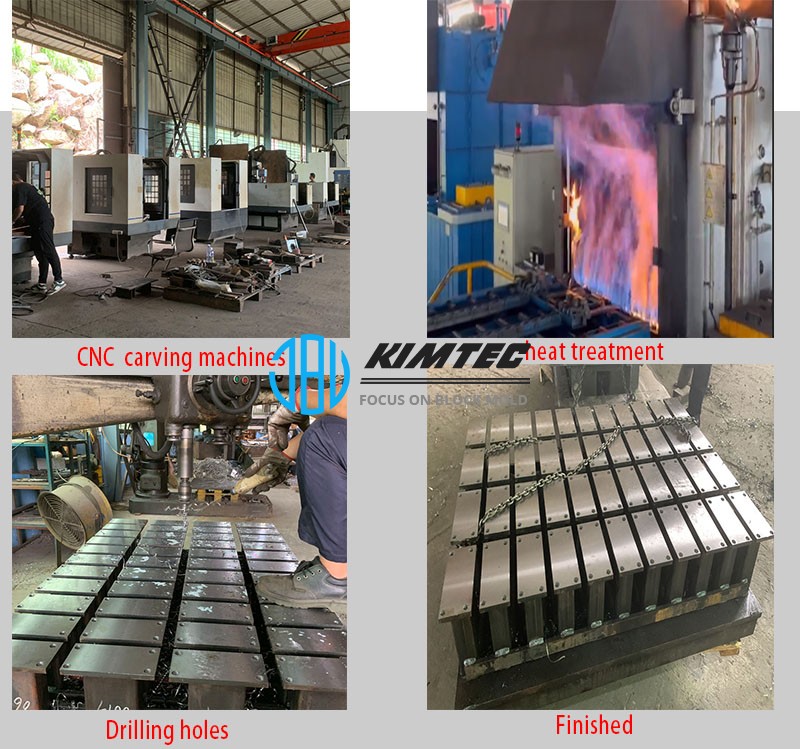

1. Der fortschrittlichste Montageprozess

A: We employ advanced welding technology and de-stress treatment. Stress in the mold material can cause deformation in the cavity and core, leading to errors in dimensions, shape, and position tolerances. This can result in products exceeding the error limits or components becoming blocked or stuck, making them unusable. To avoid this, we minimize deformation during heat treatment. We also conduct tempering after quenching to eliminate internal stress caused by machining and heat treatment, ensuring the mold functions as intended.

B: The press foot clearance related to the machine is between 0.3-0.8mm.

C: We use standard parts and apply anti-loosening treatments to high-strength connection bolts.

D: Our standardized assembly process ensures easy replacement of parts.

E: We apply high-quality, wear-resistant steel plates.

F: Unsere Formen haben eine Dämpfungsfunktion.

G: Wir bieten realisierbare digitale freie Oberflächengestaltung.

2. Um die Haltbarkeit der Form zu gewährleisten, wenden wir die folgende Behandlung an:

Carbonitriding heat treatment (60-65HRC).

A: Wir härten den Matrizenrahmen und den Pressfuß auf 60-65HRC.

B: Die Mindesthärtetiefe beträgt 1,2 mm.

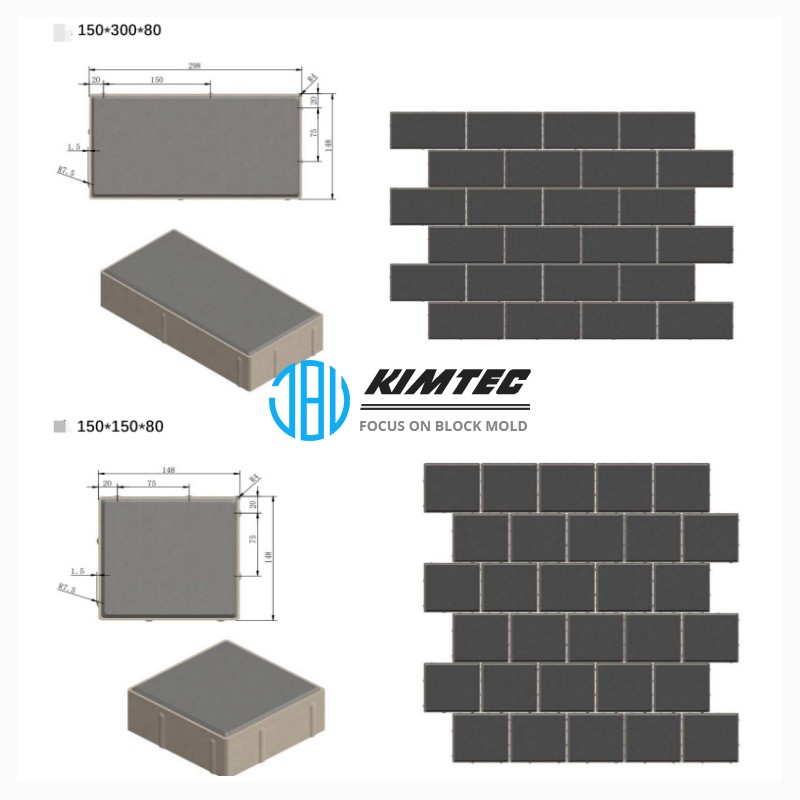

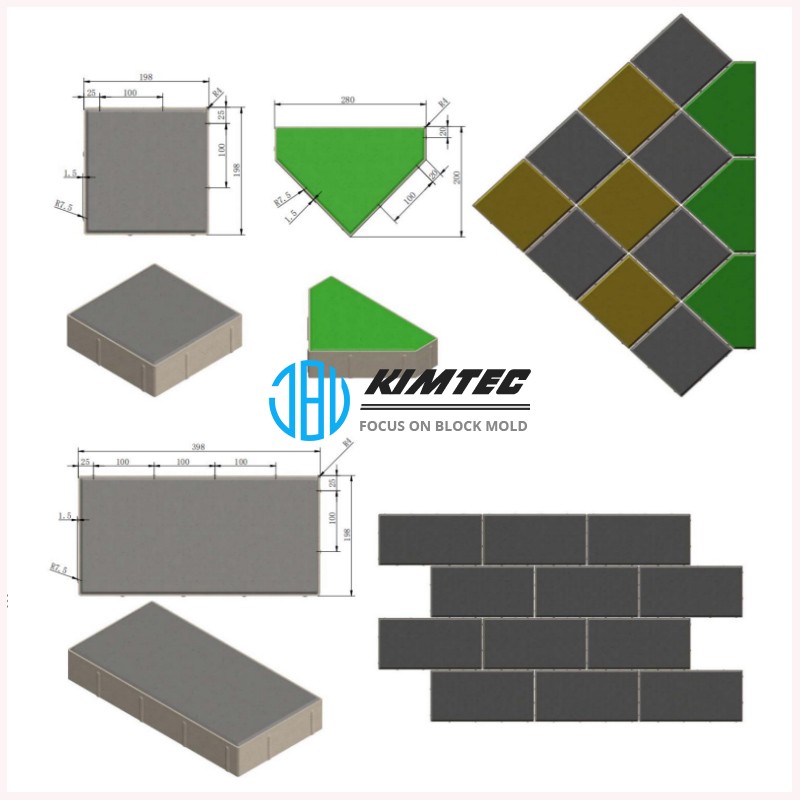

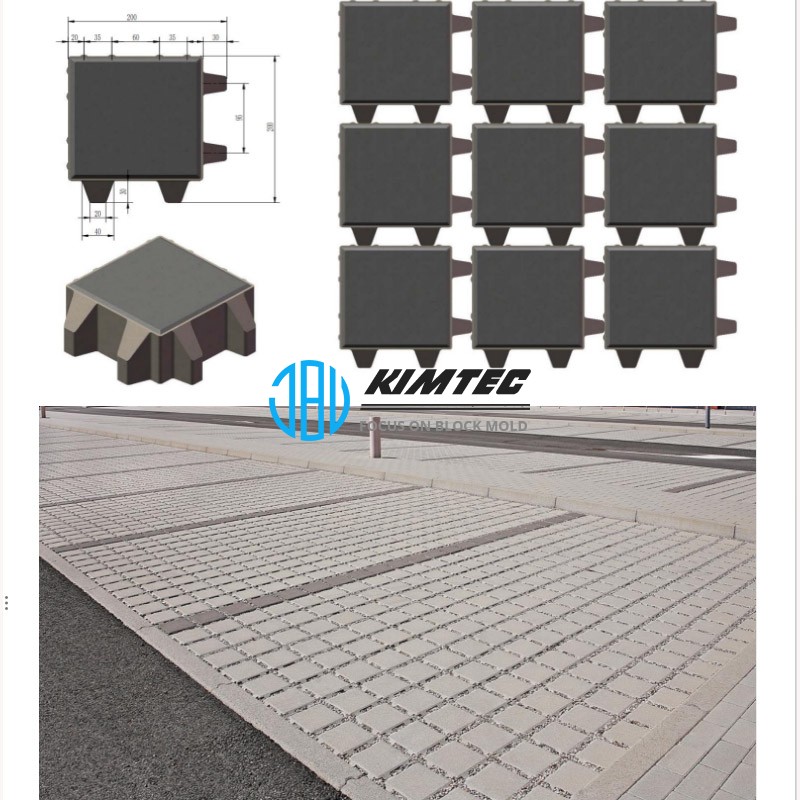

Additional Block Types for Your Reference

FAQ:

1. How can I get a quotation?

A. If you have detailed drawings of the block, please send them to us. We will quote based on that.

B. If you don’t have detailed drawings, let us know the type of block you need (e.g., hollow block, solid block, etc.). Take a picture of the block and provide the dimensions (length, width, thickness in mm).

C. What is the size of your pallet?

D. What is the size of your tamper head and the height of your down mold?

E. How will your mold connect to your machine? If you have a connection drawing, please provide it. After we receive this information, we will give you a quote as soon as possible.

2. Will the incoming mold be compatible with my machine?

We have manufactured molds for many different brands of block machines and keep related records. Some molds may already be compatible with your machine.

If necessary, you can invite an engineer to your company to take measurements. Alternatively, we can send digital images and measurements, as many of our customers do. Once we confirm the sizing, we guarantee the mold will fit your machine without any issues.

3. What are the payment terms?

To complete your order, you must pay a 50% advance via T/T. The remaining balance is due before loading.

4. How can I contact you?

You can contact us via WeChat/WhatsApp at +86-1330506196 or +86-18960287187. Thank you!