The Future of Hollow Block Mold Machines: Advancements in Technology and Automation

The future of hollow block mold technology is rapidly advancing, driven by innovations in automation and smart technology, with KBL Machinery at the forefront. Modern Block Moulds are becoming more efficient and precise through automated systems that greatly reduce manual labor while maintaining stringent quality control. As a leading construction equipment supplier, KBL Machinery is pioneering the integration of AI and machine learning into the production process, allowing machines to optimize production cycles, monitor material usage, and predict maintenance needs. These technological improvements enhance both the efficiency and the consistency of block quality, essential for meeting the rigorous demands of modern construction.

Automation also plays a critical role in reducing the environmental impact of Formen für Straßenbausteine and block production, a key area where KBL Machinery excels. Through automated energy-efficient processes, energy consumption is minimized, reducing the carbon footprint associated with hollow block mold production. Additionally, KBL Machinery has developed machines that incorporate recycled materials, such as fly ash and slag, promoting sustainability in construction. As these automated systems become more sophisticated, KBL Machinery’s machines will offer enhanced customization, enabling manufacturers to meet specific project needs with maximum efficiency and minimal waste.

Looking to the future, hollow block mold machines will increasingly feature connectivity and data-driven insights. KBL Machinery is investing in smart technologies, allowing operators to monitor production in real-time, access performance analytics, and make informed decisions that optimize overall production. As the construction industry moves toward more eco-friendly solutions, KBL Machinery is leading the way, delivering advanced, reliable, and sustainable block-making machines to meet the evolving needs of the industry.

Starting a Block Manufacturing Business with the Right Machine

- Analyze Market Demand: Before selecting a machine, assess local demand for various block types. This will help determine the required block sizes and types for your business.

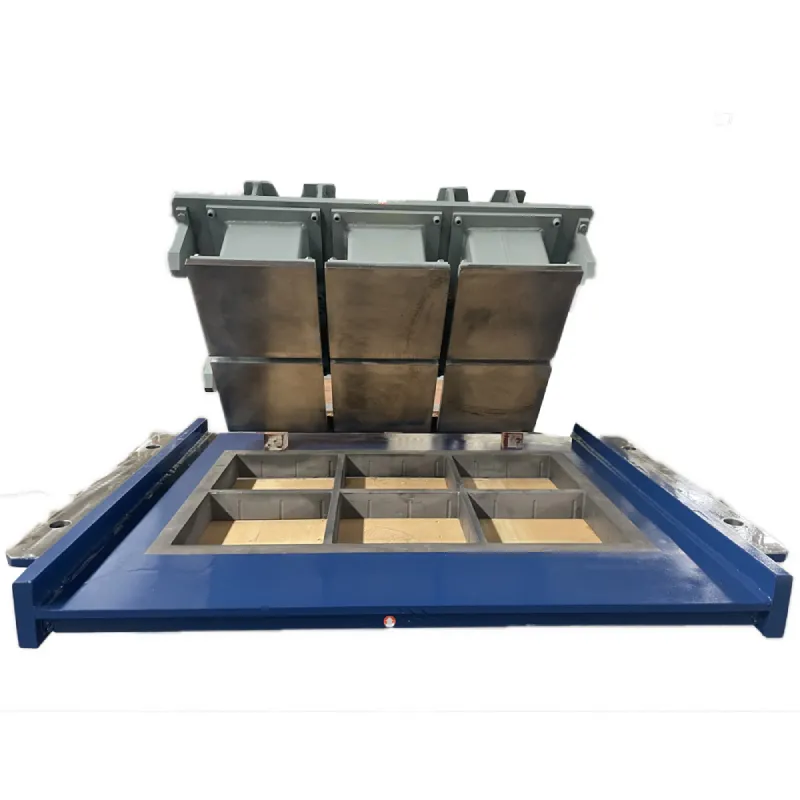

- Choose the Right Machine: Select an appropriate machine from KBL Machinery, taking into account factors like automation level, production capacity, and compatibility with different Block-Formen to achieve efficient production.

- Consider Location and Space Requirements: Establish your manufacturing plant with enough space for the machine, raw material storage, and block curing areas. Ensure accessibility for easier distribution.

- Finanzierung sichern: Estimate the costs of a hollow block mold machine, raw materials, labor, and other operational expenses, and secure funding through loans or investors.

- Schulung Ihrer Arbeitskräfte: After acquiring a machine from KBL Machinery, train employees to operate it effectively. Training reduces downtime and ensures smooth operations.

Warum KBL Machinery wählen?

KBL Machinery is a premier Lieferant von Baumaschinen, specializing in innovative, high-performance hollow block mold and Road Brick Moulds. With a commitment to efficiency, sustainability, and durability, KBL Machinery’s machines are designed to cater to diverse production needs, from small projects to large-scale applications.