The Future of Brick Making: Advanced Technology for Mold Cement Blocks

The brick manufacturing industry is undergoing a transformative shift, driven by advancements in automation and innovative technology. KBL Machinery is at the forefront of these developments, offering state-of-the-art machines designed for efficient and sustainable production of mold cement blocks. These machines utilize cutting-edge automation, integrating AI and machine learning to optimize every stage of the production process. From raw material mixing to curing, KBL Machinery ensures precision and consistency, reducing human error and enhancing the quality of the blocks produced.

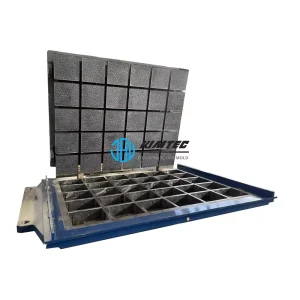

KBL Machinery's machines not only improve productivity but also align with sustainable practices by reducing energy consumption and incorporating recycled materials such as fly ash and slag. This eco-friendly approach makes their machines ideal for modern construction companies looking to minimize their carbon footprint. The versatility of these machines allows them to accommodate various Block-Formen and Road Brick Moulds, offering manufacturers flexibility to meet diverse project needs.

As a trusted construction equipment supplier, KBL Machinery is committed to innovation and connectivity. Their machines are equipped with real-time monitoring and data analysis capabilities, enabling operators to optimize performance remotely. This combination of efficiency, adaptability, and sustainability positions KBL Machinery as a leader in the industry, paving the way for a more automated and environmentally conscious future in brick manufacturing.

Wie man mit der richtigen Maschine ein Blockherstellungsunternehmen gründet

- Bewertung der Marktnachfrage: Analyze local demand for mold cement blocks and other products. This insight will guide you in selecting the appropriate machine and molds to match production requirements.

- Choose the Right Machine: KBL Machinery offers a range of machines tailored for various capacities and automation levels. Select a machine compatible with Block Moulds and Formen für Straßenbausteine to ensure versatile production capabilities.

- Location Planning: Choose a site with adequate space for machine installation, raw material storage, and curing processes. Ensure the site is easily accessible for efficient distribution to your target market.

- Finanzierung sichern: Calculate the startup costs, including the machine, raw materials, and operational expenses. Develop a financial plan and seek funding options like loans or investors to cover initial investments.

- Workforce Training: Train your staff to operate KBL Machinery’s machines effectively. Proper training minimizes downtime and enhances production efficiency, ensuring smooth operations from the outset.

Über KBL Machinery

KBL Machinery is a globally recognized Lieferant von Baumaschinen specializing in the production of innovative machines for mold cement blocks, Block Moulds, and Road Brick Moulds. With a strong focus on quality, efficiency, and sustainability, KBL Machinery delivers solutions that cater to businesses of all sizes, from small-scale operations to large industrial projects.

KBL Machinery prioritizes customer success through exceptional after-sales support, including technical assistance, operator training, and maintenance services. By combining advanced technology with a commitment to sustainability, KBL Machinery helps manufacturers improve productivity and achieve long-term success in an increasingly competitive market.

| Merkmal | Nutzen Sie |

|---|---|

| Advanced Automation | Reduces manual labor and ensures consistent production quality |

| Eco-Friendly Solutions | Incorporates recycled materials and minimizes energy consumption |

| Versatile Applications | Compatible with Block-Formen und Formen für Straßenbausteine for diverse production needs |

| Real-Time Monitoring | Optimizes performance and detects issues early for uninterrupted operations |

| Comprehensive Support | Includes training, maintenance, and spare parts for reliable, long-term use |

KBL Machinery continues to lead the industry with its commitment to innovation, sustainability, and excellence in producing high-quality equipment for mold cement blocks and beyond.