Understanding the Technology Behind Modern Concrete Paver Molds

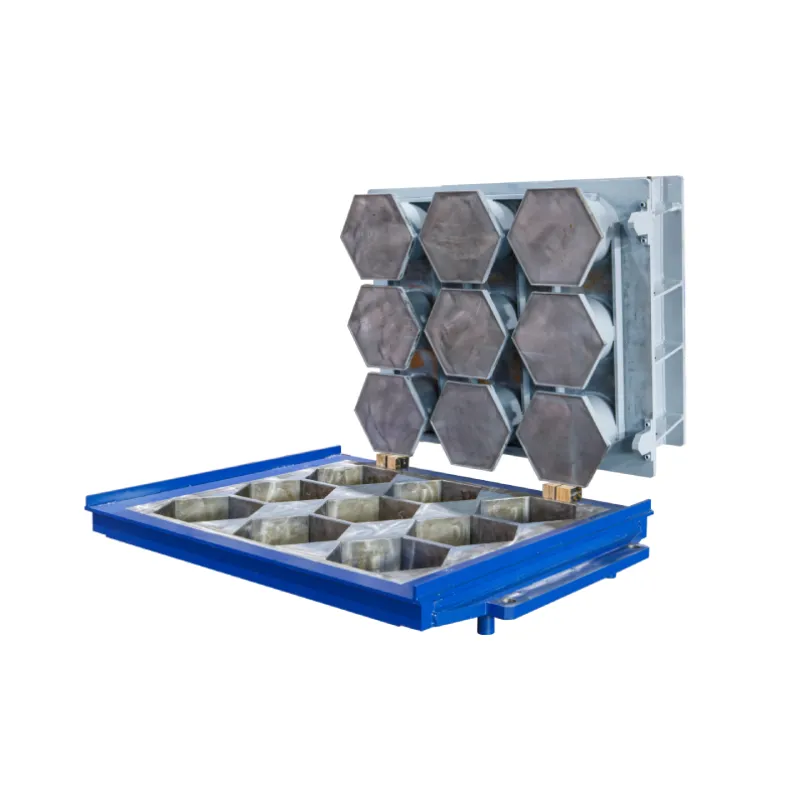

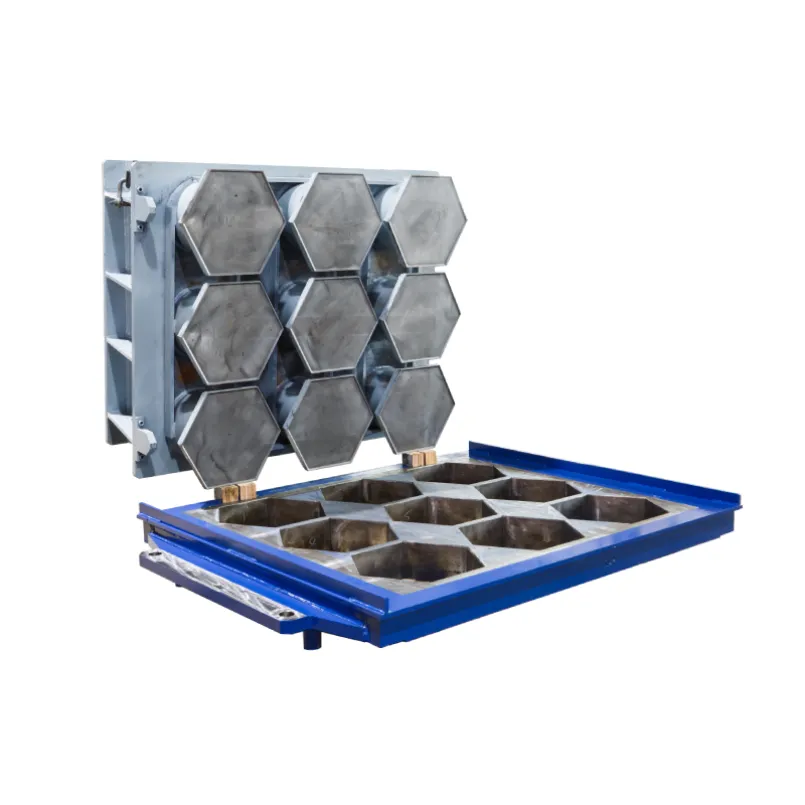

Modern concrete paver molds have transformed the construction industry, bringing advancements in efficiency, precision, and sustainability. KBL Machinery integrates cutting-edge automation and control systems into its Block-Formen, enabling manufacturers to create high-quality pavers with minimal manual input. These machines are optimized to reduce wastage, ensure consistent block dimensions, and strengthen each unit. This automation accelerates production cycles, helping companies meet higher market demands while maintaining superior quality standards.

A significant advancement in concrete paver molds lies in the integration of hydraulic systems. KBL Machinery’s molds utilize hydraulic pressure to produce denser, stronger pavers, ensuring durability and structural integrity. This hydraulic method is both energy-efficient and eco-friendly, reducing energy requirements for each batch. The precise hydraulic systems in place allow for better control, producing Formen für Straßenbausteine that meet strict industry standards for strength and consistency.

Looking forward, KBL Machinery is at the forefront of incorporating smart technology into Block Moulds. With the rise of Industry 4.0, these machines are now equipped with sensors and data analytics, enabling operators to monitor production in real-time, identify potential issues, and optimize performance remotely. This blend of automation, hydraulic efficiency, and smart technology keeps KBL Machinery at the forefront, providing molds that are both innovative and cost-effective for today’s construction equipment supplier needs.

Key Benefits of Using a Hydraulic Concrete Paver Molds Machine

- Enhanced Block Durability: Hydraulic concrete paver molds from KBL Machinery consistently apply uniform pressure, producing durable pavers ideal for diverse construction projects.

- Energie-Effizienz: With hydraulic systems that use less energy while delivering high performance, KBL Machinery’s paver molds ensure cost-effective and eco-friendly production.

- Consistency and Precision: Advanced hydraulic technology from KBL Machinery provides precise molding control, ensuring that each block is uniform in size and quality, reducing waste, and improving production efficiency.

- Lower Maintenance Requirements: The durable design of KBL Machinery’s hydraulic systems results in fewer maintenance needs compared to traditional systems. The robust construction and reduced moving parts extend the life of the molds and decrease downtime.

KBL Machinery - Trusted Partner in Construction Equipment

At KBL Machinery, we are committed to delivering high-quality and high-performance Block Moulds and Road Brick Moulds. Our expertise ensures that our equipment offers advanced technology, superior efficiency, and sustainability. We understand the unique challenges faced by the Lieferant von Baumaschinen industry and provide solutions to help our clients optimize their processes. From large infrastructure projects to smaller-scale ventures, KBL Machinery is dedicated to enhancing your capabilities with reliable and cutting-edge equipment.

Beyond offering top-tier products, KBL Machinery excels in customer support, emphasizing long-term relationships and client success. From initial consultations to comprehensive after-sales service, we prioritize meeting specific production requirements for each customer. Our focus on innovation and a customer-first approach has made KBL Machinery a trusted global partner, helping clients reach new productivity and success levels.