Mold Technical Specifications

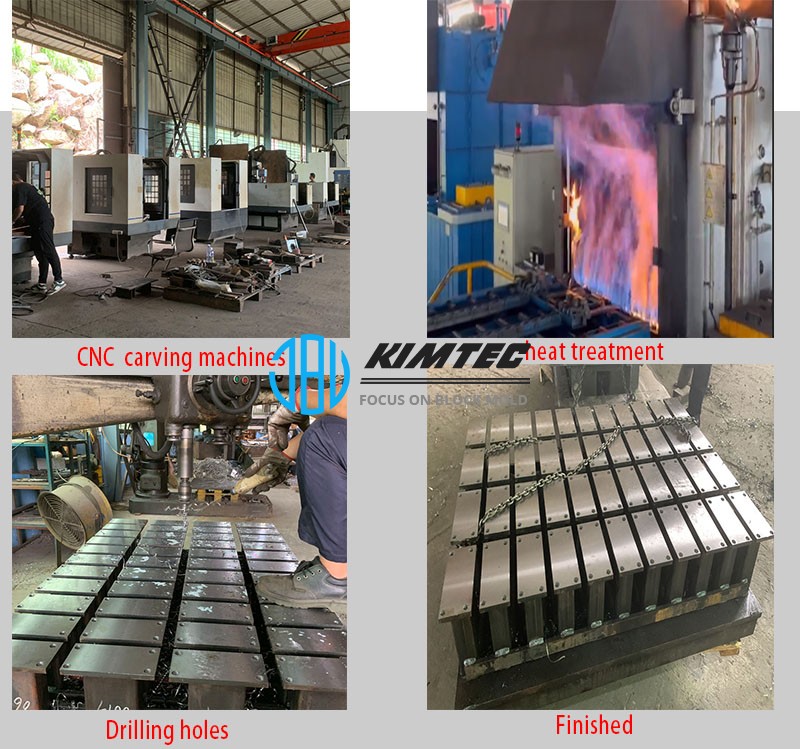

1. The Most Advanced Assembly Process

A: We apply advanced welding technology and de-stress treatment. If stress is present in the mold material, the cavity and core can deform during use. This leads to errors in dimensions, shape, and position tolerances, causing products to exceed error limits. It may also block or jam well-matched components, making them unusable. Therefore, we minimize deformation during heat treatment. After quenching, we perform tempering to eliminate internal stress caused by machining and heat treatment, ensuring the mold functions as designed.

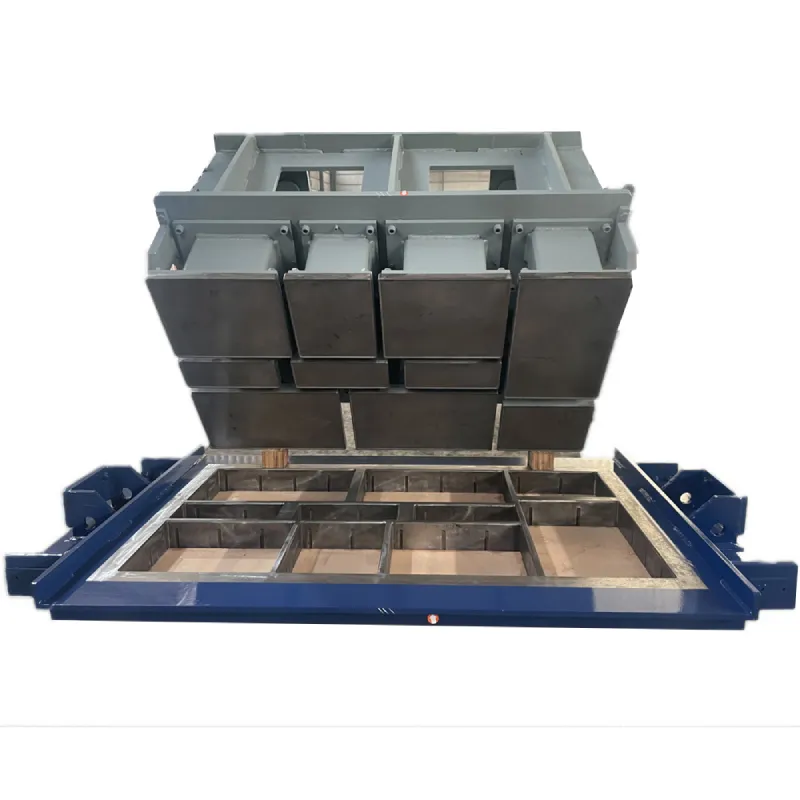

B: The press foot clearance relative to the machine is between 0.3-0.8mm.

C: We use standard parts and apply anti-loosening treatment to high-strength connection bolts.

D: Our standardized assembly process makes part replacement easy.

E: We utilize high-quality, wear-resistant steel plates.

F: Our molds feature a damping function.

G: We offer realizable digital free surface design.

2. To ensure mold durability, we apply the following treatment:

We conduct carbonitriding heat treatment (60-65HRC).

A: We harden the die frame and press foot to 60-65HRC.

B: The minimum hardening depth is 1.2mm.

FAQ:

- How can I get the quotations?

A. If you have detailed drawings of the block you need, send them to us for review, and we will provide a quote based on that.

B. If you don’t have detailed drawings, let us know the type of block you need, such as hollow or solid blocks. Send us a picture of the block along with its dimensions (lengthwidththickness in mm).

C. Share the size of your pallet.

D. Provide the size of your tamper head and the height of your down mold.

E. Explain how your mold connects to your machine. If you have a connection drawing, please share it.

Once we receive your information, we will quote for you as soon as possible. - What is the delivery time?

After receiving the deposit, common block molds take 20-25 work days, while high-end block molds take 30-40 work days. - Will the incoming mold be compatible with my machine?

We manufacture molds for various block machine brands and keep detailed records, so some molds may already suit your machine.

If needed, you can invite an engineer to take measurements, or we can guide you to send photos and measurements digitally, as many customers do.

After confirming the sizing, the mold we send will fit your machine perfectly, so no worries! - How can I contact you?

Reach us via WeChat/WhatsApp at +86-1330506196 or +86-18960287187. Thank you!