Product Overview

Concrete batching machine is used for the aggregates batching for concrete mixing station. The aggregates can be 2-4 types, such as crushed stone, sand and other industry wastes. The proportion of each aggregate is weighed automatically controlled by microcomputer. There are hopper cumulative weighing, belt cumulative weighing and separated hopper weighing can be chosen.

The Weighing Type and Bin Numbers Can be Customized

1. Hopper Cumulative Weighing

Concrete batching machine with hopper cumulative weighing discharges the aggregates into the same one hopper for weighing. The discharging is automatically controlled to ensure the accuracy. It has features of simple structure, low cost and easy maintenance.

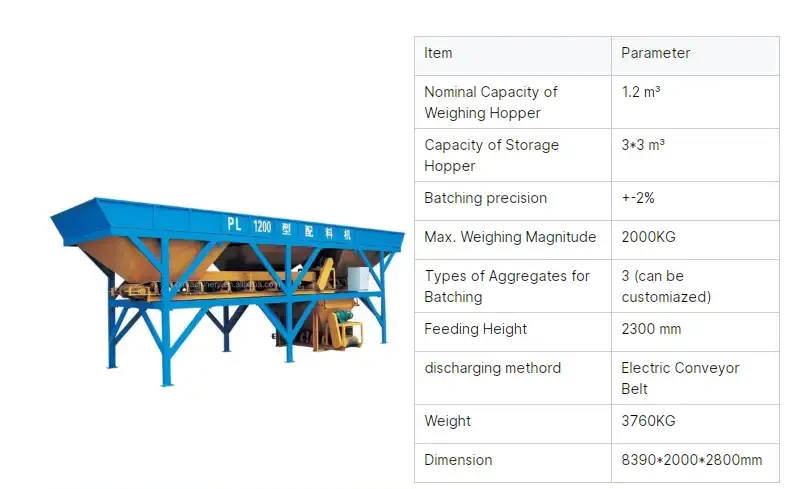

Hopper cumulative weighing is used for small batching capacity machines, such as PL800 (48m³/h), PL1200 (60m³/h), PL1600 (80m³/h). Usually thistype concrete batching machines have 2-3 bins.

2. Belt Cumulative Weighing

Concrete batching machine with belt cumulative weighing discharges all the aggregates onto the delivery belt with a long hopper.

It has features of big capacity, fast opening and delivery.

Belt cumulative weighing is usually used for PL1600 (80m³/h) and PL2400 (120m³/h) with 3-4 bins.

3. Separated Hopper Weighing

Concrete batching machine with separated weighing discharges each aggregate into a separated hopper with weighing device. Its main

advantage is high accuracy weighing, but its cost is higher than others, because of the advanced design.

Separated hopper weighing is usually used for PL2400 (120m³/h), LP3200 (160m³/h) or largerbatching machines.