Enhancing Quality with Precast Concrete Kerbs: Innovations in Block Mould Technology

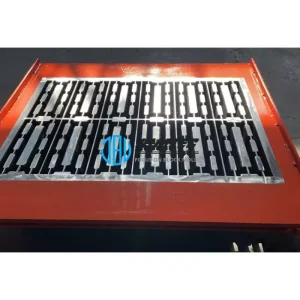

Enhancing the quality and efficiency of precast concrete kerbs is now more achievable with advanced block mould technology. KBL Machinery, a leading construction equipment supplier, specializes in innovative Block Moulds and Road Brick Moulds that streamline the production of precast concrete elements. By integrating automation and precision engineering, these moulds ensure consistency and uniformity in every kerb produced. Advanced automation systems, now standard in KBL Machinery's mould designs, reduce human error and improve quality by automating the mixing, moulding, and curing processes, resulting in precast concrete kerbs that meet exact specifications for strength and durability.

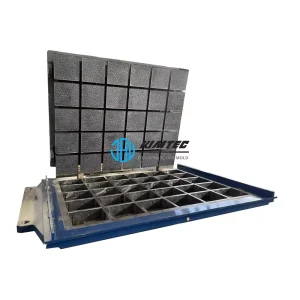

Using Block Moulds and Road Brick Moulds from KBL Machinery not only enhances product quality but also offers significant benefits in production efficiency. These moulds are crafted to accommodate a range of raw materials, including eco-friendly and recycled options, enabling manufacturers to align with sustainable practices. With technology that allows precise control over kerb density and structure, KBL Machinery's moulds improve the longevity and resilience of concrete kerbs, making them highly resistant to environmental wear and tear.

Key Factors in Choosing Reliable Block Moulds for Precast Concrete Kerbs

- Durability and Precision: KBL Machinery's block moulds are engineered for high precision, ensuring each precast concrete kerb produced is consistent and meets quality standards. Their Block Moulds and Road Brick Moulds are designed to withstand continuous use, which is essential for maintaining efficiency in high-demand environments.

- Customization and Flexibility: Recognizing the varied requirements of construction projects, KBL Machinery offers customizable moulds that allow for different kerb sizes and specifications, making them an ideal construction equipment supplier for diverse production needs.

- Sustainability and Energy Efficiency: KBL Machinery emphasizes sustainability in its mould designs. These moulds optimize material usage and energy consumption, helping reduce costs and environmental impact during kerb production.

| Features | Benefits |

|---|---|

| Automated Precision | Ensures high-quality, consistent precast concrete kerbs for all construction projects. |

| Customizable Mould Designs | Offers flexibility to produce various kerb shapes and sizes, adapting to market demands. |

| Energy Efficiency | Reduces operational costs and aligns with eco-friendly practices. |

| Durable Material | Extends mould lifespan, minimizing the need for replacements and reducing downtime. |

| After-Sales Support | KBL Machinery provides robust support for maintenance, training, and spare parts availability. |

Why KBL Machinery Stands Out as a Top Construction Equipment Supplier

With years of expertise in the industry, KBL Machinery is a trusted construction equipment supplier committed to delivering high-performance solutions for the production of precast concrete kerbs, Block Moulds, and Road Brick Moulds. Their dedication to innovation and customer satisfaction is evident through their comprehensive range of moulds and after-sales support, which includes maintenance, technical assistance, and spare parts supply. Businesses choosing KBL Machinery benefit from durable equipment that enhances operational efficiency, improves quality, and supports sustainable production practices. This focus on quality and reliability makes KBL Machinery the go-to partner for those seeking excellence in the construction industry.