Energy-Efficient and Eco-Friendly Brick Making Machines: Focus on Path Moulds for Sustainable Construction

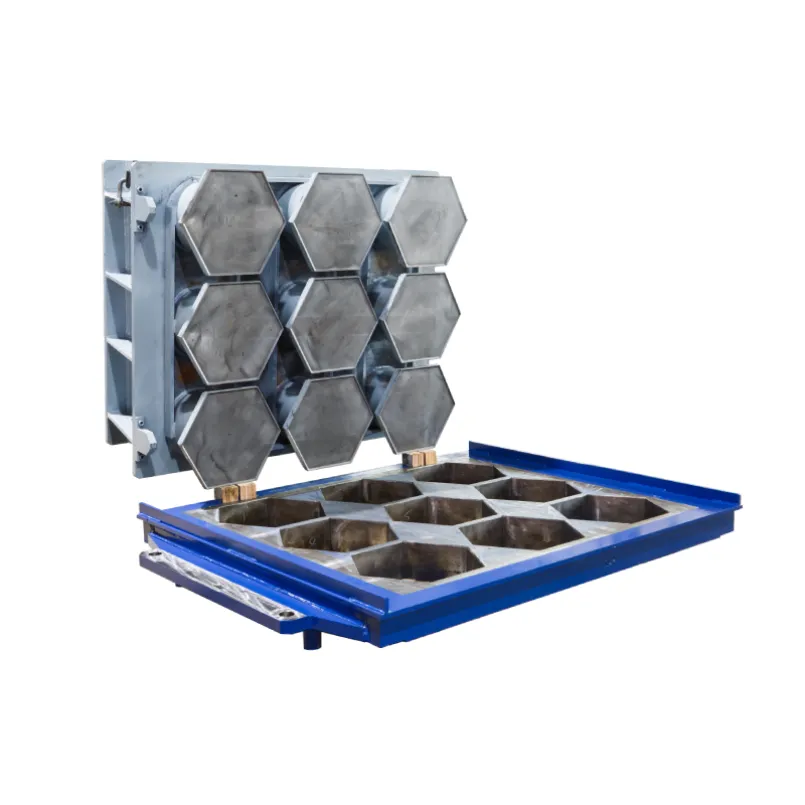

Energy-efficient and eco-friendly path moulds are at the heart of the industry's shift towards sustainable construction. These innovative machines are designed to minimize energy consumption while maximizing production output, making them an essential investment for manufacturers aiming to reduce costs and environmental footprints. KBL Machinery’s path moulds are equipped with advanced automation systems and optimized production processes, enabling companies to produce high-quality bricks and paving slabs with minimal energy usage. By incorporating path moulds into their production lines, manufacturers can align with global sustainability goals and enhance their market competitiveness through eco-friendly solutions.

The demand for eco-friendly construction materials is growing, and KBL Machinery’s path moulds are designed to support this trend. These machines allow manufacturers to use sustainable, locally sourced materials or recycled aggregates, further reducing the environmental impact of the brick-making process. Additionally, KBL Machinery's path moulds ensure that each brick and slab produced meets the highest standards of strength, durability, and uniformity, which is crucial for successful long-term projects.

Not only do path moulds provide environmental benefits, but they also offer significant cost savings. By reducing energy consumption and enhancing production efficiency, these machines help businesses cut down on utility bills. Furthermore, the faster production times and minimized waste boost overall productivity, making path moulds from KBL Machinery a smart investment for any construction business looking to stay ahead in the green building sector.

Key Considerations When Choosing Block Moulds and Path Moulds

1. Production Capacity

When selecting path moulds or block moulds, production capacity is one of the most important factors. Machines with higher capacity ensure you can meet demand without delays, especially when running large-scale operations. If you need to produce a significant number of paving slabs or construction blocks, investing in higher-capacity path moulds will prevent production bottlenecks. KBL Machinery offers a range of path moulds and block moulds that cater to both small and large-scale production needs, giving you the flexibility to choose based on your specific requirements.

2. Automation Level

The level of automation in path moulds and block moulds will determine the efficiency of your operation. Fully automated machines are ideal for large-scale production because they reduce labor costs and increase speed. Semi-automatic or manual path moulds and block moulds, while more affordable, may require additional labor and time to meet high production demands. KBL Machinery’s range of automated and semi-automated options for path moulds ensures that you can find the right solution to meet your efficiency goals and labor resources.

3. Energy Efficiency

Energy consumption is a crucial consideration when purchasing path moulds and block moulds. The machines should be designed to use less energy while producing high-quality output. KBL Machinery's path moulds are equipped with energy-saving technologies, reducing the overall operational costs by optimizing energy usage during the brick and block production processes. By choosing path moulds that minimize energy consumption, companies can cut costs while contributing to more sustainable construction practices.

4. Quality of Output

The consistency and durability of bricks or paving slabs produced with path moulds and block moulds are vital to your construction projects. Machines that produce high-quality, uniform bricks are essential for ensuring that the final product meets industry standards. KBL Machinery’s path moulds and block moulds are engineered for precision, ensuring that each brick or slab has the necessary strength and consistency. This quality control helps businesses avoid costly rework and ensures that customers receive reliable, durable products.

5. After-Sales Support and Maintenance

Investing in path moulds or block moulds from KBL Machinery guarantees access to excellent after-sales support. Regular maintenance and technical assistance are vital for keeping production lines running smoothly. KBL Machinery offers comprehensive customer service, including training, maintenance support, and easy access to spare parts for path moulds and block moulds, ensuring that your equipment continues to perform at optimal levels for years.

About KBL Machinery

KBL Machinery is a leading construction equipment supplier, specializing in the design and production of high-performance brick-making machines, including path moulds and block moulds. With a focus on sustainability, efficiency, and innovation, KBL Machinery offers a variety of machines that meet the diverse needs of the construction industry. Our path moulds and block moulds are designed to optimize production processes while reducing energy consumption, waste, and costs. As a trusted construction equipment supplier, KBL Machinery also provides exceptional after-sales service, ensuring that businesses have the support they need to succeed in an increasingly competitive market.

Key Benefits of KBL Machinery’s Path Moulds and Block Moulds

| Feature | Benefit |

|---|---|

| Path Moulds | Energy-efficient and versatile, capable of producing high-quality paving slabs and blocks for various applications. |

| Block Moulds | Robust design that ensures uniformity and durability in brick production, suitable for large-scale operations. |

| Energy Efficiency | Advanced technology that reduces energy consumption while maintaining high production output. |

| Customization Options | Flexible machine designs that allow for a variety of brick and slab types to meet specific project needs. |

| After-Sales Support | Reliable customer support with training, maintenance, and spare parts, ensuring long-term operational success. |