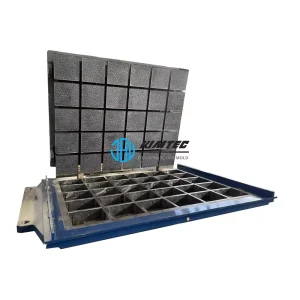

China concrete block making machine factory

KBL Machinery’s concrete block making machine is designed to streamline the process of producing blocks for construction. Its advanced automation reduces the need for manual labor, improving efficiency. This machine ensures high output with consistent block quality. KBL Machinery emphasizes precision and performance in its equipment.

The Role of Concrete Block Making Machines in Modern Construction

Concrete block making machines have become an essential component in modern construction, transforming the way materials are produced and enhancing the efficiency of construction processes. KBL Machinery designs state-of-the-art Block Making Machines that optimize production, allowing companies to manufacture high-quality blocks in large quantities. This advanced automation drastically reduces the need for manual labor, cutting costs while ensuring that each block meets the necessary standards for modern infrastructure projects. With the growing demand for construction materials, KBL Machinery’s block making machines provide the scalability and efficiency that construction companies need to meet tight deadlines.

In addition to increasing production efficiency, KBL Machinery’s concrete block making machines offer superior precision, producing blocks with uniform size, strength, and durability. The machines are capable of working with various materials, enabling construction companies to produce blocks suitable for a wide range of applications, from residential buildings to industrial complexes. The consistency of blocks produced by KBL Machinery ensures improved structural integrity in construction projects, reducing the risk of defects and promoting long-term sustainability.

Moreover, the eco-friendly features of KBL Machinery’s concrete block making machines are helping construction companies align with sustainability goals. These machines are designed with energy-efficient technology and the ability to incorporate recycled materials, reducing both environmental impact and operational costs. As the construction industry shifts towards more sustainable practices, KBL Machinery continues to lead the way with innovative solutions that enhance productivity and support green building initiatives.

The Benefits of Automated Brick Making Machines

- Increased Production Efficiency: Automated brick-making machines from KBL Machinery streamline the production process, allowing businesses to produce large quantities of bricks in a short time. This efficiency helps companies meet the demands of larger construction projects while improving profitability.

- Consistent Quality: Automation ensures that each brick is manufactured to precise dimensions and strength. KBL Machinery’s brick making machines maintain consistent quality across all products, minimizing defects and improving the overall integrity of construction projects.

- Reduced Labor Costs: By automating the brick-making process, KBL Machinery helps companies significantly reduce labor costs. Fewer workers are needed to operate the machines, allowing resources to be reallocated more effectively.

- Energy Efficiency: KBL Machinery designs its machines to be energy efficient, reducing power consumption while maintaining high production capacity. This not only lowers electricity costs but also supports environmentally friendly construction practices.

- Customization Flexibility: KBL Machinery’s Block Making Machines offer flexibility in brick type, size, and design. This adaptability allows businesses to produce various brick styles without needing multiple machines, providing versatility for diverse construction needs.

By investing in KBL Machinery’s concrete block making machines, companies can expect a reduction in production costs, an increase in productivity, and a commitment to sustainable construction practices, making KBL Machinery a leading construction equipment supplier in the industry.