Brick Machine Making Automatic: Transforming the Building Materials Industry

Smart brick machine making automatic systems are revolutionizing the building materials industry by incorporating automation and advanced technology into production, resulting in heightened efficiency and precision. These machines utilize cutting-edge sensors, AI-driven controls, and real-time data analysis to monitor and adjust various stages of brick production, from raw material preparation to final curing. This automation reduces the need for manual labor, ensuring that every brick produced is consistent in size, strength, and quality. The precision offered by automatic brick making machines minimizes waste, optimizes resource usage, and reduces production costs, allowing manufacturers to meet high industry standards while significantly improving productivity.

In addition to efficiency, brick machine making automatic systems contribute to sustainability in the building materials sector. By leveraging real-time data, these machines optimize energy consumption and raw material usage, helping reduce environmental footprints. Many of these machines are designed to work with eco-friendly materials, making them ideal for companies focused on green building practices. As sustainability becomes a priority in the construction industry, Block Making Machines help manufacturers align with regulatory requirements and consumer demands for environmentally responsible products. These smart machines enable manufacturers to lead in this transition, producing high-quality bricks with reduced environmental impact.

Moreover, automatic brick making machines offer flexibility and scalability, allowing manufacturers to easily adapt to changing market demands. Programmable functions enable the production of a variety of brick types, sizes, and compositions without significant downtime. This adaptability allows companies to respond swiftly to custom orders or evolving trends in the construction industry, providing a competitive advantage. As a result, these machines are not only transforming brick production but also enhancing the overall efficiency and responsiveness of manufacturing operations in the building materials sector.

Multi-Functional Brick Machines: Meeting Diverse Market Demands

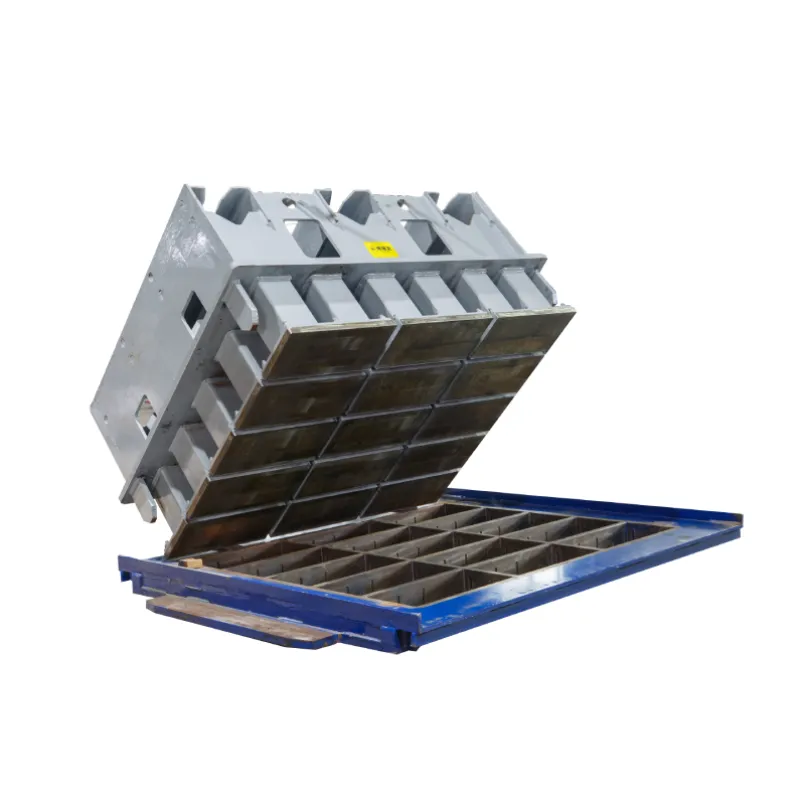

- Versatility in Brick Types: KBL Machinery’s Block Making Machines produce various brick shapes, sizes, and materials, including hollow, solid, interlocking, and decorative bricks.

- Adaptability to Raw Materials: These machines handle a wide range of raw materials, including clay, cement, fly ash, and sand, making them versatile for different construction requirements.

- Customization for Projects: With programmable settings, automatic brick making machines can quickly adapt to specific project requirements, ideal for specialized construction needs.

- Increased Efficiency: Multi-functional machines integrate several processes, reducing downtime and increasing production capacity.

- Cost-Effectiveness: By consolidating multiple functions into one machine, manufacturers lower capital investment and maintenance costs while maximizing production output.

| Key Features of Multi-Functional Brick Machines | Benefits |

|---|---|

| Versatility in Brick Types | Produces a wide range of brick shapes and sizes. |

| Raw Material Adaptability | Supports various raw materials for diverse construction needs. |

| Programmable Customization | Quickly adapts to different project specifications. |

| Increased Efficiency | Reduces downtime and boosts productivity. |

| Cost-Effectiveness | Lowers equipment and maintenance costs. |

KBL Machinery: A Trusted Construction Equipment Supplier

KBL Machinery is recognized as a leading construction equipment supplier, offering high-quality brick making machines and Block Making Machines to meet a wide range of production needs. With a focus on innovation and energy efficiency, KBL Machinery helps businesses streamline production processes while ensuring superior product quality. Their commitment to customer success is reflected in exceptional after-sales support, which includes training, maintenance services, and readily available spare parts. Choosing KBL Machinery means partnering with a reliable supplier dedicated to helping businesses achieve long-term operational efficiency and sustained growth in a competitive market.