Blocks Making Machine Automatic: Driving Sustainable and Efficient Construction

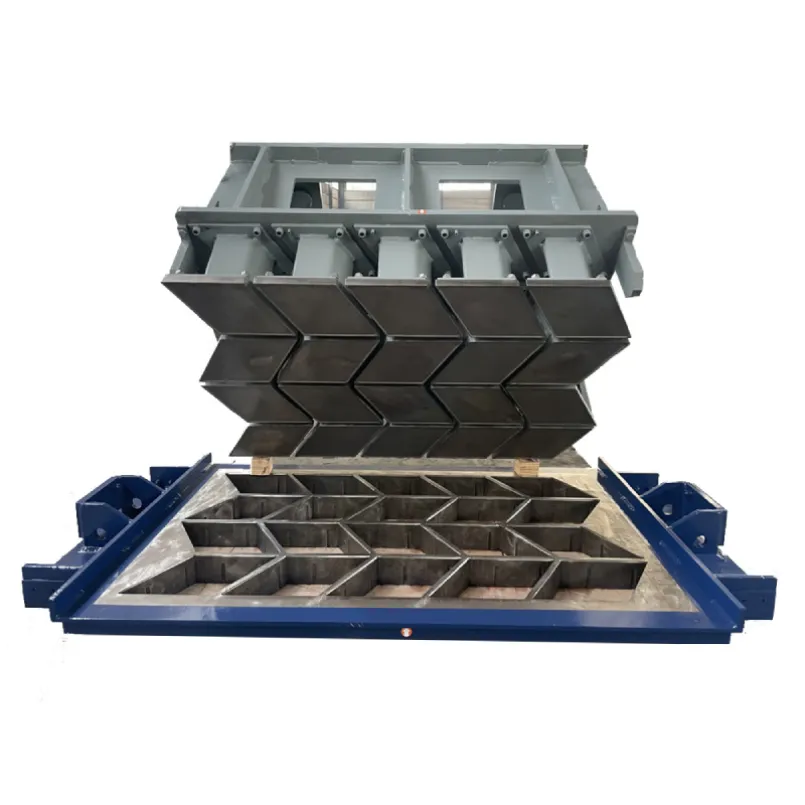

In the evolving construction industry, energy-efficient and eco-friendly blocks making machine automatic systems are becoming essential to drive sustainable practices. These machines are engineered to minimize energy consumption while maximizing production output, helping manufacturers reduce operational costs and lower their environmental footprint. Utilizing advanced technology such as automated controls and optimized processes, KBL Machinery’s brick making machines enable the production of high-quality blocks with less energy, aligning with global sustainability goals and regulations. By adopting such energy-efficient machinery, businesses not only contribute to environmental conservation but also gain a competitive edge by lowering long-term costs and enhancing productivity.

Moreover, blocks making machine automatic models from KBL Machinery incorporate the use of sustainable materials, such as recycled or locally sourced raw inputs. These machines allow manufacturers to produce eco-friendly blocks, free from harmful chemicals, meeting the growing demand for green building solutions. As construction projects increasingly prioritize sustainability, companies can leverage these machines to strengthen their market position while contributing to environmentally conscious practices. Adopting automatic brick making machines ensures that manufacturers can meet customer expectations, reduce waste, and stay ahead in the competitive construction landscape.

Beyond environmental benefits, the use of automatic Block Making Machines also leads to improved operational efficiency. Lower energy consumption translates to reduced utility bills, while faster production cycles allow manufacturers to meet deadlines without compromising quality. The ability to produce blocks with fewer resources further boosts productivity, making these machines a smart investment for businesses aiming for long-term growth. Additionally, adopting sustainable technologies enhances a company’s reputation, attracting eco-conscious partners and clients. With sustainability becoming a core business priority, KBL Machinery offers a clear path to industry leadership through its blocks making machine automatic solutions.

Five Key Factors to Consider When Purchasing Block Making Equipment

- Production Capacity: The production capacity of a blocks making machine automatic system is crucial. It’s essential to assess both current and future production needs to ensure the machine can meet demand. For businesses aiming to produce a high volume of blocks, investing in a machine with a higher capacity will prevent production delays and ensure timely project completion.

- Automation Level: The level of automation in brick making machines varies, from manual to fully automatic systems. Fully automated machines require minimal human intervention, significantly improving production efficiency and reducing labor costs. However, semi-automatic systems may offer a balance between affordability and efficiency, particularly for medium-scale operations.

- Energy Efficiency: Energy consumption directly impacts long-term operational costs. KBL Machinery’s Block Making Machines are designed to be energy efficient, reducing overall energy bills while maintaining high output levels. By investing in energy-efficient machines, businesses can meet sustainability goals and save on operational expenses.

- Quality of Output: Ensuring that the machine produces high-quality blocks consistently is vital for the success of any construction project. KBL Machinery focuses on delivering machines that produce bricks with uniform strength, size, and durability. High-quality output prevents structural issues and reduces the need for costly rework.

- After-Sales Support and Maintenance: Reliable after-sales support is essential for the longevity of your Block Making Machine. KBL Machinery offers comprehensive support, including staff training, maintenance services, and quick access to spare parts. Choosing a supplier with strong after-sales service minimizes downtime and ensures smooth operations.

| Key Considerations for Purchasing Block Making Machines | Benefits |

|---|---|

| Production Capacity | Ensures scalability to meet future demand. |

| Automation Level | Reduces labor costs and increases efficiency. |

| Energy Efficiency | Lowers operational costs and aligns with sustainability. |

| Quality of Output | Guarantees consistent, high-quality blocks. |

| After-Sales Support | Minimizes downtime and ensures smooth operations. |

About KBL Machinery

As a leading construction equipment supplier, KBL Machinery specializes in producing advanced brick making machines and Block Making Machines that cater to the diverse needs of modern construction. Known for innovation, durability, and sustainability, KBL Machinery delivers cutting-edge solutions that enhance production efficiency and ensure consistent quality. With a strong emphasis on customer satisfaction, KBL Machinery provides comprehensive after-sales support, ensuring that their clients can achieve long-term success. Whether you’re working on small-scale or large industrial projects, KBL Machinery is the trusted partner for energy-efficient and high-performance solutions.