Automatic Hollow Block Making Machine: A New Era of Efficient Production

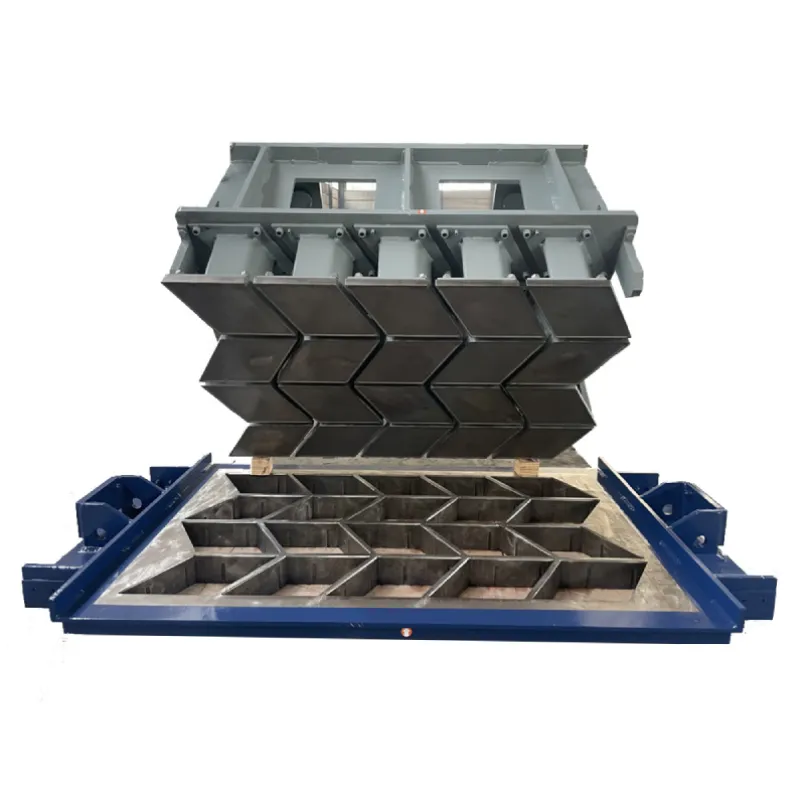

The automatic hollow block making machine is revolutionizing the brick manufacturing industry by offering unprecedented efficiency and precision. Using advanced technologies such as robotics, sensors, and AI-driven controls, these machines automate the entire process—from raw material mixing to molding, drying, and stacking. The automation drastically reduces manual intervention, ensuring consistent product quality and minimizing human error. By streamlining production, the automatic hollow block making machine significantly increases output while maintaining precise control over block size, shape, and composition, leading to high-quality products that meet stringent industry standards.

A key benefit of fully automated Block Making Machines is their ability to operate continuously with minimal downtime. Equipped with real-time monitoring systems, these machines can detect and address issues before they lead to costly disruptions. Moreover, automated machines are designed to optimize raw material usage and energy consumption, reducing waste and lowering production costs. This improvement in sustainability and cost efficiency makes fully automated systems a smart investment for large-scale operations. Not only do these machines contribute to environmental sustainability, but they also deliver long-term cost savings for businesses.

In addition to increased efficiency, automatic hollow block making machines offer unmatched flexibility. They can be easily adjusted to produce different types of bricks, from standard solid bricks to more complex, custom designs. This adaptability allows manufacturers to respond quickly to changing market demands, making it easier to produce a wide variety of block types without extensive downtime or reconfiguration. As a result, these machines help businesses stay competitive in an ever-evolving industry.

Maintenance and Repair of Brick Making Machines: Best Practices for Extending Equipment Lifespan

- Regular Inspection and Cleaning: Routine inspections and cleanings are vital to prolonging the life of a brick making machine. Regular checks for wear and tear on components like belts, gears, and hydraulic systems help prevent unexpected breakdowns. Keeping the machine clean prevents the buildup of dust and debris, which can interfere with performance.

- Lubrication of Moving Parts: Proper lubrication minimizes friction between moving parts, such as bearings and gears, reducing wear and extending the machine’s lifespan. Using the correct lubricants and following a regular lubrication schedule as recommended by KBL Machinery ensures smooth operation.

- Monitoring and Replacing Worn Parts: Key components, including molds, belts, and gears, experience wear with frequent use. Regular monitoring and timely replacement of these parts prevent costly downtime and ensure continued efficiency.

- Periodic Calibration: Ensuring that sensors and automated controls are calibrated regularly is essential for maintaining precision in block production. Following KBL Machinery’s calibration guidelines helps ensure consistent output quality and machine efficiency.

- Employee Training on Operation and Safety: Well-trained operators are key to prolonging the life of automatic hollow block making machines. Proper training not only minimizes operational risks but also ensures that minor issues are addressed promptly before they escalate into major problems.

| Key Maintenance Practices | Benefits |

|---|---|

| Regular Inspection | Prevents unexpected breakdowns and prolongs equipment life. |

| Lubrication of Parts | Reduces wear and ensures smooth operation. |

| Monitoring & Replacing Worn Parts | Minimizes downtime and keeps production running efficiently. |

| Periodic Calibration | Maintains precision and consistency in production. |

| Employee Training | Ensures safe, efficient operation and prompt issue resolution. |

KBL Machinery: A Leading Construction Equipment Supplier

KBL Machinery is a renowned construction equipment supplier specializing in high-performance brick making machines and Block Making Machines. With a commitment to innovation and quality, KBL Machinery provides reliable and efficient solutions tailored to the needs of modern construction businesses. Their range of machines, including the automatic hollow block making machine, is designed for energy efficiency, sustainability, and precision.

In addition to delivering top-tier machinery, KBL Machinery offers comprehensive after-sales support, including technical assistance, training, and maintenance services. By choosing KBL Machinery, businesses gain a trusted partner committed to helping them achieve operational efficiency, cost savings, and long-term success.