Complete Brick Production Line Solutions

Kimberly Machinery offers a complete range of production equipment, including the brick making machine, high-precision brick mold solutions, and a full set of auxiliary systems for batching, mixing, and pallet handling. As one of the leading block making machine manufacturers in the industry, we supply reliable and efficient machinery for global construction and building material companies. For customized configurations or turnkey services, Contact us today.

-

XX1000 Hydraulic Pressing Machine

-

QT4-15 Brick/Block Making Machine

-

Solid Brick Mould Slab Mold Kerbstone Rain Gutter Stone Paving Stone Making

-

Interlocking Hollow Concrete Block Mold Mould Design Molding Supplier from China

-

MASA HESS Molding Hollow Blocks Molds China Supplier

-

Thermally Insulated Hollow Blocks Mold Mould Moule for Building

-

Hourdi Moule Grass Stone Mold Eared Ceiling Block For Concrete Brick Machine

-

High-End Paving Stone Ceiling Block Mould Hollow Block Molder China Supplier

-

Solid Brick Mold Hollow Block Mould for Brick Making Machine Like MASA HESS TIGER

-

Different Types of Hollow Brick Block Moulds

-

High-End Hollow Brick Block Ceiling Paving Stone Interlock Rain-Gutter Slab And Special Molds for MASS HESS TIGER ZENITH ETC

-

Hourdi Parpa Moule Concrete Block Mould for Block Brick Making Machines

Kimberly Machinery – Complete Solutions for Modern Brick & Block Production

Kimberly Machinery specializes in delivering integrated production systems, ranging from core forming machines and engineered molds to advanced auxiliary equipment. With strong manufacturing capacity, professional engineering support, and global service coverage, we help clients build efficient, stable, and scalable brick production line operations for both commercial and industrial applications.Core Forming Equipment

Our equipment portfolio includes a versatile selection of forming machines suitable for various types of building materials. The lineup contains automatic and semi-automatic systems designed for different capacities and production scales. This series also includes the concrete brick making machine, engineered for consistent density, high strength, and optimized cycle times. In addition, customized configurations are available for environmentally friendly production methods such as the cement brick making machine, which ensures uniform compaction and reduced energy consumption during operation.High-Precision Moulds

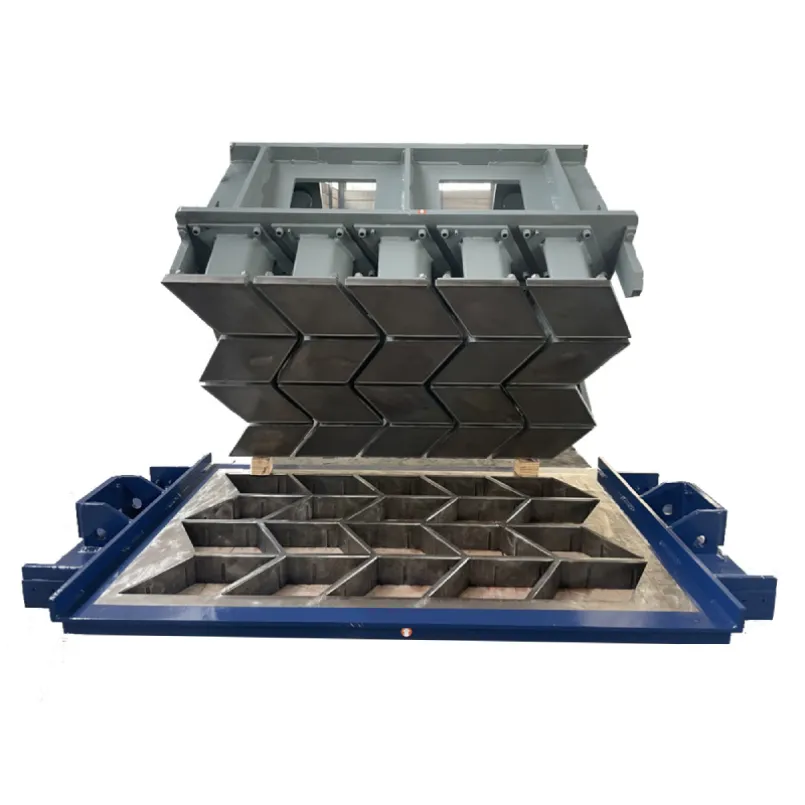

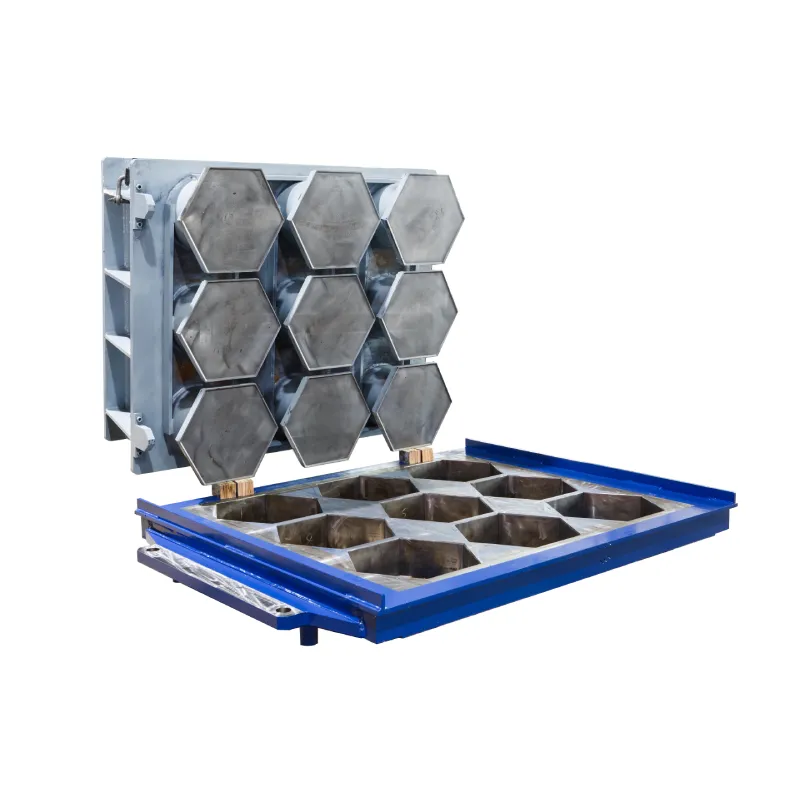

Kimberly Machinery provides a diverse range of molds tailored for hollow blocks, pavers, curbstones, grass blocks, interlocking bricks, and other specialized designs. Each mold is manufactured using high-strength alloy steel and advanced heat-treatment processes to guarantee long service life and dimensional accuracy. For operators seeking reliable mold solutions for high-output facilities, we offer fully compatible molds designed to work with different machine brands. Our brick mold options ensure stable performance and support various brick designs without compromising product quality.Auxiliary Equipment for Complete Production Lines

To support efficient and continuous manufacturing, Kimberly Machinery supplies a full set of auxiliary machines, including mixing systems, batching equipment, pallet solutions, and handling tools.- Concrete Mixing Systems– ensure uniform material blending for consistent forming results.

- Batching Machines– guarantee precise proportioning of aggregates, cement, and additives.

- Pallet Systems– include PVC, bamboo, and fiber pallets to support brick forming, curing, and logistics.

- Supporting Tools & Components– vibration tables, stackers, conveyors, and electrical control cabinets.

Additional Specialized Machinery

Kimberly Machinery also offers specific-purpose equipment such as the auto brick making machine, designed for fully automated lines that require minimal manpower. For customers focusing on versatile manufacturing environments, the bricks manufacturing machine provides a flexible configuration suitable for producing multiple product types with quick mold-change capabilities.Why Choose Kimberly Machinery?

- Comprehensive manufacturing coverage: forming machines, molds, and auxiliary systems

- Strong engineering expertise and customizable solutions

- Durable, industrial-grade equipment with long service life

- Global technical support, installation guidance, and training