Why Concrete Paving Mold Machines are Essential for Construction Projects

Concrete paving mold machines have become a cornerstone of modern construction, offering the ability to produce large quantities of durable and high-quality paving products with precision and speed. KBL Machinery leads the way in designing advanced machines that simplify the manufacturing process, enabling construction companies to meet tight project timelines without compromising on product quality. By automating the labor-intensive task of paving product manufacturing, these machines reduce labor costs while enhancing productivity.

One of the primary reasons concrete paving mold machines are indispensable is their ability to create paving blocks with uniform size, shape, and strength. The blocks produced by KBL Machinery meet stringent industry standards, ensuring they are robust enough to endure heavy loads and environmental wear. This consistency in quality enhances the longevity and reliability of paving projects, minimizing future maintenance needs and structural concerns.

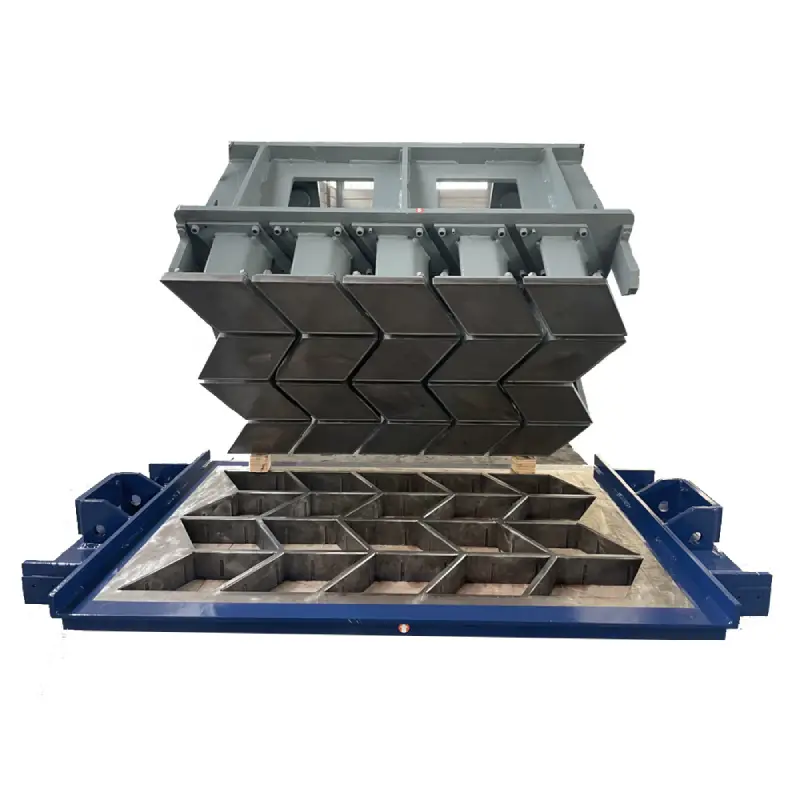

Modern machines from KBL Machinery are also highly versatile, offering the flexibility to use various Block Moulds and Road Brick Moulds for different project requirements. This adaptability allows manufacturers to customize the size, design, and composition of their paving blocks, accommodating unique client specifications, including eco-friendly or aesthetically tailored products. With the ability to minimize waste and maximize efficiency, KBL Machinery helps construction companies contribute to sustainable building practices.

Custom Solutions in Concrete Paving Mold Machine Design

Tailored Production Capacity: KBL Machinery designs machines with customizable capacities to suit diverse project scales, from small paving installations to large industrial applications.

Versatility in Product Types: These machines can work with a variety of Block Moulds and Road Brick Moulds, producing paving blocks of different shapes, materials, and designs to meet diverse client demands.

Automation Options: Whether businesses require manual, semi-automatic, or fully automated solutions, KBL Machinery provides tailored automation levels to optimize production while minimizing labor costs.

Energy Efficiency: With advanced energy-saving features, KBL Machinery’s machines reduce electricity consumption while maintaining high production output, ensuring cost-effective and eco-friendly operations.

Durable and Robust Design: Built with top-quality materials, these machines are engineered to withstand intensive use and harsh environmental conditions, ensuring longevity and minimal maintenance requirements.

Why Choose KBL Machinery?

As a trusted construction equipment supplier, KBL Machinery is committed to providing innovative, reliable, and high-performance machines for producing paving products using concrete paving molds, Block Moulds, and Road Brick Moulds. With years of expertise, KBL Machinery ensures their machines are optimized for precision, durability, and energy efficiency, enabling businesses to enhance their production capabilities and achieve long-term success.

KBL Machinery stands out for its exceptional customer support, offering technical training, maintenance services, and after-sales assistance to help clients maximize the value of their investment. With a focus on cutting-edge technology and client satisfaction, KBL Machinery remains the preferred partner for construction businesses worldwide.

| Feature | Benefit |

|---|---|

| Versatile Design | Compatible with concrete paving molds, Block Moulds, and Road Brick Moulds |

| Energy Efficiency | Reduces operational costs while supporting sustainable practices |

| Customizable Capacity | Scales to meet small- and large-scale project requirements |

| Precision Manufacturing | Ensures uniform and durable paving blocks for long-lasting construction |

| Comprehensive Support | Offers training, maintenance, and technical assistance for uninterrupted operations |

KBL Machinery continues to innovate, delivering solutions that empower businesses to achieve excellence in paving product manufacturing, ensuring efficiency, sustainability, and reliability in every project.