Cement Block Making Machine: Ensuring Reliable Productivity for Large-Scale Projects

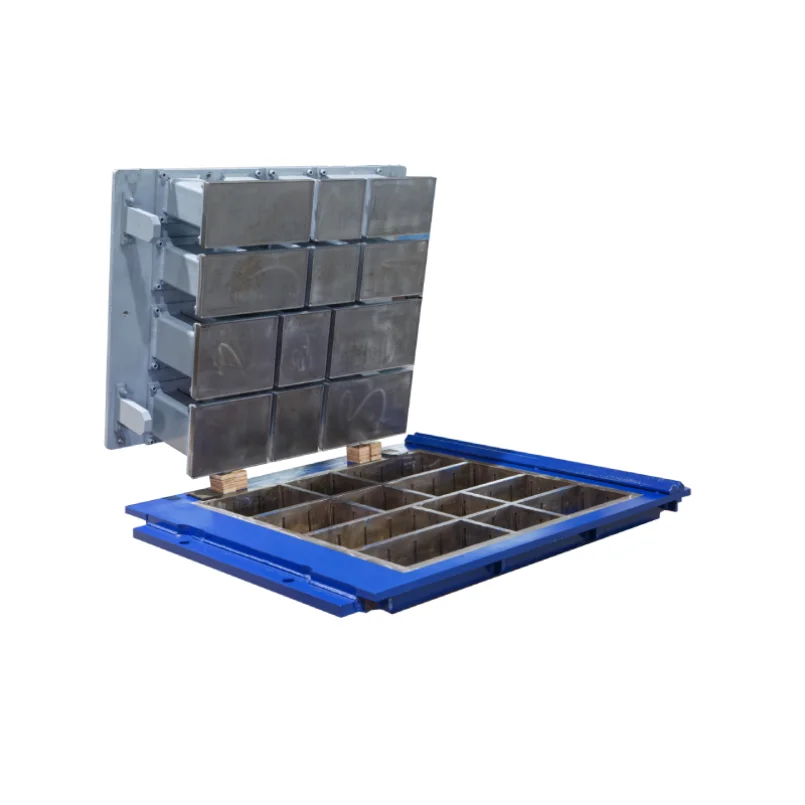

A cement block making machine is essential for ensuring reliable productivity in large-scale construction projects, where efficiency and consistency are critical. These machines are designed to handle large volumes of raw materials and produce a significant number of blocks in each production cycle, making them ideal for construction projects that require high output in a short period. Equipped with advanced automation and precision controls, cement block making machines can operate continuously with minimal downtime, enabling manufacturers to meet tight deadlines and maintain a steady supply without compromising on quality. By producing at scale while adhering to strict standards, these machines ensure that even the most demanding projects run smoothly.

One of the key benefits of a cement block making machine is its ability to streamline production processes, reducing bottlenecks and enhancing overall efficiency. These machines incorporate automated systems for material mixing, molding, and curing, allowing for faster and more accurate production compared to traditional methods. Features such as automated batching and real-time monitoring enable adjustments to be made on the fly, optimizing output and minimizing waste. This leads to lower operational costs and increased profitability, making Block Making Machines a valuable investment for manufacturers aiming to scale their production capabilities.

Additionally, cement block making machines offer the flexibility to meet various project requirements. They can be programmed to produce different types of blocks—hollow, solid, or interlocking—based on specific needs. This adaptability enables manufacturers to serve a wide range of clients, from large infrastructure projects to custom architectural designs. Investing in a cement block making machine allows manufacturers to boost their production capacities and respond effectively to evolving market demands, ensuring long-term success in competitive markets.

Long-Term ROI of Investing in Block Making Machines: From Costs to Benefits

- Reduced Labor Costs: One of the immediate benefits of investing in a brick making machine is the significant reduction in labor costs. These machines automate most production processes, from raw material mixing to block molding and curing, which minimizes the need for a large labor force. By decreasing manual labor, businesses can save on wages and other associated costs like training and supervision.

- Increased Production Efficiency: Modern cement block making machines are designed to produce blocks at a faster rate compared to traditional methods. Automated systems optimize production, enabling large volumes of blocks to be produced in less time. This increased efficiency allows businesses to fulfill more orders and reduce lead times, directly impacting revenue growth.

- Energy Savings: Many cement block making machines come equipped with energy-efficient technologies that reduce overall power consumption. These machines feature optimized motors, intelligent power management systems, and energy-saving modes that adjust usage based on production needs. Over time, lower utility bills contribute to significant savings.

- Consistent Product Quality: Automation ensures consistent block quality by reducing the variability that often occurs with manual processes. Each block is produced to exact specifications, minimizing defects and waste. This reliability in output reduces rework and associated costs, improving profitability and strengthening customer satisfaction.

- Longer Equipment Lifespan: High-quality cement block making machines are built for durability, featuring robust components that withstand heavy use. Many machines include advanced self-diagnostic systems to monitor key components, allowing preventive maintenance to be performed before issues escalate. This ensures the longevity of the machine, reducing the frequency and cost of repairs.

| Benefits of Investing in Cement Block Making Machines | Description |

|---|---|

| Reduced Labor Costs | Automates processes to reduce the need for manual labor. |

| Increased Efficiency | Produces large volumes of blocks faster, boosting output. |

| Energy Savings | Energy-efficient features lower utility costs. |

| Consistent Quality | Produces uniform blocks, reducing waste and defects. |

| Durable Design | Ensures a long lifespan and reduces maintenance costs. |

KBL Machinery: A Trusted Construction Equipment Supplier

KBL Machinery is a leading construction equipment supplier, providing high-performance cement block making machines, brick making machines, and Block Making Machines. With a focus on innovation, energy efficiency, and reliability, KBL Machinery caters to a wide range of industrial needs, from small-scale operations to large-scale projects. Designed to optimize production processes, KBL Machinery’s machines help businesses enhance efficiency, reduce costs, and meet stringent industry standards. The company is also known for its exceptional after-sales support, offering technical assistance, maintenance, and training to ensure long-term success in the competitive construction market.