Why Investing in a Quality Cement Block Maker Pays Off

Investing in a high-quality cement block maker, such as those offered by KBL Machinery, provides long-term value for businesses in the construction industry. These advanced machines ensure the consistent production of durable, high-strength blocks, reducing the risk of defects and waste. KBL Machinery’s precision-engineered Block Making Machines are designed to meet large-scale demand while maintaining top-notch quality. This consistency not only boosts operational efficiency but also helps businesses build a strong reputation for reliability and performance.

In addition to improving productivity, a quality cement block maker from KBL Machinery delivers superior energy efficiency, which leads to lower operational costs. These machines are equipped with automated hydraulic systems that minimize energy use without compromising performance. The result is an eco-friendly production process that meets sustainability goals while significantly cutting long-term power expenses. Optimizing material usage and reducing labor costs allows businesses to achieve significant savings over time.

Moreover, the durability of KBL Machinery’s Block Making Machines means less frequent maintenance and minimal downtime. Built to handle heavy-duty industrial demands, these machines ensure uninterrupted operation, reducing the risk of costly breakdowns. The reliability and long-term performance of these machines translate into lower maintenance costs and greater profitability, making them an excellent investment for any business looking to stay competitive in the market.

| Benefits of Investing | Advantages |

|---|---|

| Consistent Block Quality | Reduces product defects and wastage |

| Energy Efficiency | Lower energy costs with advanced hydraulic systems |

| Durability and Reliability | Minimal downtime and reduced maintenance |

| Long-Term Profitability | Lower operational costs and higher returns on investment |

Brick Making Machine Maintenance: Tips for Longevity and Efficiency

- Regular Cleaning:

Maintaining cleanliness is essential for optimal machine performance. KBL Machinery recommends regular cleaning of all parts of your brick making machine to prevent material buildup that can lead to blockages and reduced efficiency. - Lubrication of Moving Parts:

Proper lubrication is key to keeping the machine running smoothly. KBL Machinery advises using high-quality lubricants and sticking to a regular maintenance schedule for your cement block maker to reduce wear and tear on moving parts. - Hydraulic System Inspections:

For Block Making Machines equipped with hydraulic systems, regular checks for leaks and pressure issues are critical. Ensuring the system operates at the correct pressure will extend the machine's lifespan and avoid malfunctions. - Component Inspections:

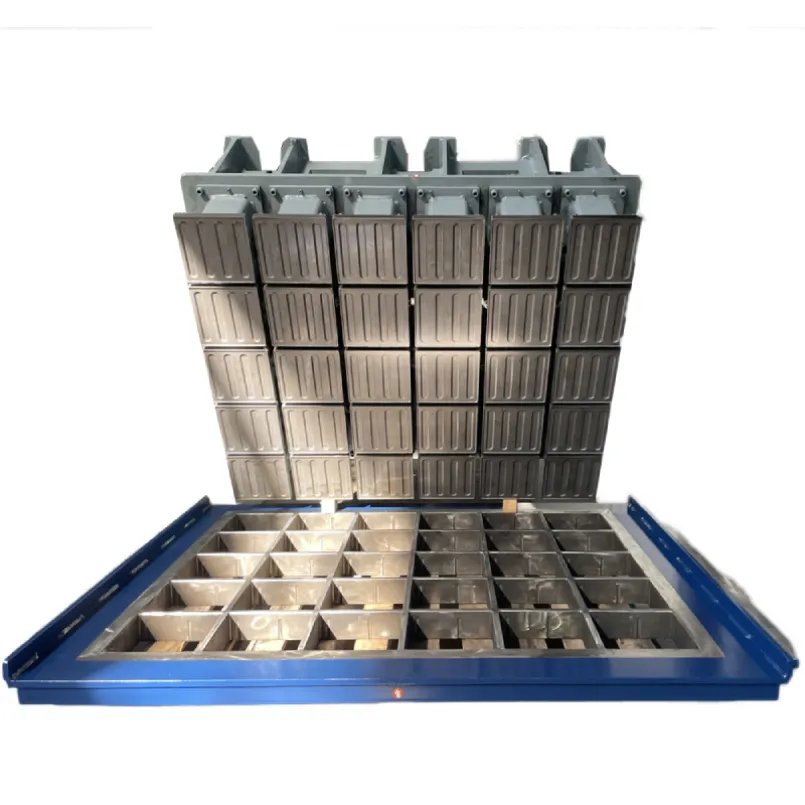

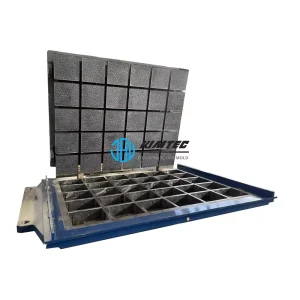

Inspect components like molds, belts, and bearings regularly to catch signs of wear or damage early. Replacing worn-out parts on time helps maintain production efficiency and prevents more costly repairs down the line. - Proper Storage and Protection:

When not in use, storing your brick making machine in a clean, dry space helps preserve its functionality. Protecting the machine from harsh weather conditions extends its service life and keeps it operating at peak efficiency.

About KBL Machinery

KBL Machinery is a leading construction equipment supplier, providing innovative solutions in the production of cement block makers, brick making machines, and Block Making Machines. With a strong focus on sustainability, efficiency, and advanced technology, our machines are engineered to meet the evolving needs of the construction industry. At KBL Machinery, we are dedicated to providing durable, precision-engineered equipment that supports eco-friendly production. Our commitment to customer service and reliability has made us a trusted partner for businesses worldwide, delivering cutting-edge machinery and expert support.