Maximize Efficiency in Block Production with Interlock Mold for Sale Designs

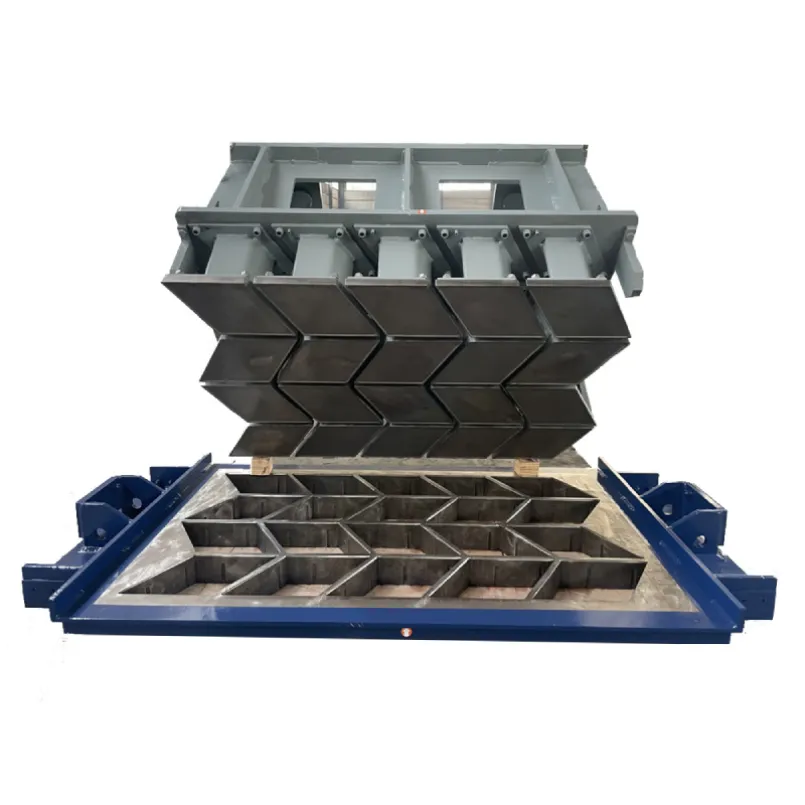

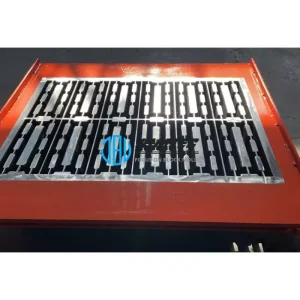

Maximizing efficiency in block production is crucial for manufacturers aiming to meet diverse project demands without sacrificing quality or speed. KBL Machinery's interlock mold for sale provides an innovative, flexible solution that allows for seamless modifications and adjustments during production. These moulds are customizable, enabling the creation of various block sizes and shapes without the need for multiple mould sets. This adaptability not only reduces downtime when switching between product types but also helps manufacturers maintain high production rates, addressing diverse customer requirements and boosting operational efficiency.

In addition to flexibility, KBL Machinery's interlock mold for sale is designed with precision and durability in mind. These moulds ensure that every block meets strict industry standards for strength and uniformity, while the advanced engineering minimizes defects, reducing material waste and enhancing production line efficiency. Made from premium materials, these moulds are built to withstand continuous, high-volume use, ensuring that production remains consistent over time.

Cost savings are another major advantage of KBL Machinery's interlock mold for sale. By investing in these modular mould systems, manufacturers can reduce the need for frequent replacements and minimize maintenance expenses, resulting in long-term operational savings. The adaptability of these moulds also provides manufacturers with the flexibility needed to respond quickly to shifting market demands, ensuring they remain competitive while maintaining high efficiency.

| Benefits of KBL Machinery's Interlock Mold for Sale | Key Advantages |

|---|---|

| Customization | Flexibility to produce different block shapes and sizes without multiple mould sets |

| Precision & Durability | Ensures each block meets industry standards, with minimal defects and material waste |

| Long-Term Cost Savings | Reduces mould replacement frequency and lowers maintenance costs |

How Interlock Mold for Sale and Block Moulds Support Sustainable Construction Practices

Sustainability in construction is more important than ever, and KBL Machinery's interlock mold for sale along with its Block Moulds are designed to support eco-friendly building practices. Precision engineering helps minimize production defects, reducing material waste and making better use of raw materials. This reduction in waste contributes directly to a smaller environmental footprint, aligning production processes with sustainable goals.

The durability of KBL Machinery's interlock mold for sale and Block Moulds plays a crucial role in sustainability as well. These moulds are built to last, reducing the need for frequent replacements, which conserves resources and lowers the energy associated with manufacturing new moulds. The long lifespan of these moulds helps construction businesses maintain eco-friendly operations by reducing the need for new materials over time.

In addition, KBL Machinery's Road Brick Moulds and Block Moulds are designed to incorporate recycled materials into production, promoting green building practices. This flexibility allows manufacturers to produce high-quality blocks while using fewer environmentally harmful resources, ensuring that they can meet the rising demand for sustainable construction solutions.

Contribution to Green Building Standards

KBL Machinery's interlock mold for sale, Block Moulds, and Road Brick Moulds provide manufacturers with the tools they need to optimize production processes while supporting sustainability efforts. These moulds are ideal for companies aiming to meet the requirements for certifications such as LEED, contributing to the development of greener construction projects.

As a leading construction equipment supplier, KBL Machinery provides solutions that not only enhance production efficiency but also support the industry's shift towards more sustainable and responsible building practices.