What Is The Difference Between a Mud Brick Making Machine And a Block Brick Making Machine?

Oct 28, 2024

In the world of construction, the demand for sustainable and efficient building materials has led to the development of various brick making technologies. Among these, mud brick making machines and block brick making machines are gaining popularity for their unique capabilities and applications.

What are Mud Brick Making Machines?

Mud brick making machines are specialized equipment designed to produce bricks from natural soil, commonly mixed with water and sometimes other organic materials like straw. This traditional method results in eco-friendly bricks that are often used in low-cost housing and environmentally sustainable projects. The production process typically involves compressing the mud mixture into molds and allowing it to dry naturally, avoiding the need for high-temperature firing.

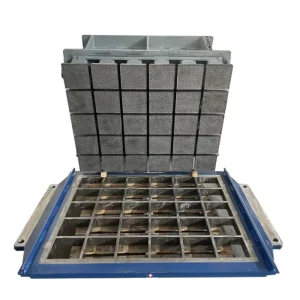

What are Block Brick Making Machines?

In contrast, block brick making machines focus on creating cement-based bricks, commonly referred to as concrete blocks. These machines use a combination of cement, sand, gravel, and water, mixed to form a slurry that is then shaped into blocks. The production process may include vibration and curing techniques, which enhance the strength and durability of the final product. Block bricks are widely utilized in various construction projects, from residential buildings to infrastructure development.

Key Differences Between Mud Brick and Block Brick Making Machines

Raw Materials:

Mud Brick Making Machines: Utilize natural soil and organic additives.

Block Brick Making Machines: Rely on cement and aggregates for production.

Production Process:

Mud Brick Making Machines: Employ a simple method of compressing and air-drying the mud mixture.

Block Brick Making Machines: Involve mixing, molding, and curing, often using advanced technologies to improve quality.

Strength and Applications:

Mud Bricks: Generally weaker, suited for low-rise structures and eco-friendly projects.

Block Bricks: Offer higher strength, making them ideal for a wide range of construction applications, including load-bearing walls.

Environmental Impact:

Mud Brick Making Machines: Considered more sustainable due to the use of natural materials and lower energy consumption.

Block Brick Making Machines: While effective, they contribute to higher carbon emissions due to cement production.

Market Demand:

Mud Bricks: Gaining traction in rural and developing areas focusing on sustainable building practices.

Block Bricks: Continue to dominate urban construction markets due to their versatility and strength.

Conclusion

As the construction industry evolves, understanding the differences between mud brick making machines and block brick making machines is crucial for builders and developers. Each machine serves distinct needs and contributes to the diverse landscape of modern construction. Whether opting for the eco-friendly mud bricks or the robust concrete blocks, both technologies play vital roles in shaping the future of sustainable building practices.

About us

KBLmachinery is a leading supplier of brick making machines, offering a wide range of high-quality equipment designed to meet the diverse needs of the construction industry. With a commitment to innovation and sustainability, KBLmachinery provides solutions for producing both traditional mud bricks and durable concrete blocks. Their machines are engineered for efficiency, reliability, and ease of use, making them ideal for builders and developers looking to enhance productivity while minimizing environmental impact. Whether for large-scale projects or small enterprises, KBLmachinery is dedicated to delivering exceptional value and performance in brick manufacturing.